Teflon PTFE Hose for Demanding Chemical and Industrial Applications: A Comprehensive Technical Guide

Introduction

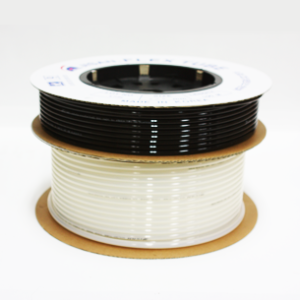

In industries where extreme chemical resistance, robust performance under varying temperatures, and superior electrical insulation are critical, the Teflon (PTFE) Hose stands as a premier solution. Engineered from high-purity polytetrafluoroethylene (PTFE), this hose is designed for demanding applications, including chemical transfer, fuel and oil handling, and insulated fluid lines. Its exceptional chemical inertness, oil and fuel resistance, and wide temperature capability make it a versatile choice for environments requiring reliable performance under harsh conditions.

The PTFE hose, available in sizes ranging from JT0402 (4 × 2 mm) to JT2018 (20 × 18 mm), offers working pressures of 7–25 kg/cm² and burst pressures up to 100 kg/cm², depending on the diameter. With a temperature range of -65°C to 260°C (media-dependent), it excels in both low- and high-temperature settings. Optional perfluoroalkoxy (PFA) construction is available for applications requiring specific material properties, such as enhanced clarity or flexibility. This hose is ideal for industries like chemical processing, aerospace, automotive, and electronics, where durability and safety are paramount.

This article provides a detailed technical analysis of the Teflon PTFE Hose, covering its specifications, materials, key features, applications, comparisons, benefits, limitations, and maintenance guidelines. Aimed at engineers, system designers, and technical professionals, this guide offers in-depth insights into how the PTFE hose meets the rigorous demands of modern industrial applications, ensuring efficiency, safety, and longevity.

Technical Overview

The Teflon PTFE Hose is a high-performance tubing solution engineered for applications requiring maximum chemical resistance, thermal stability, and electrical insulation. Constructed from virgin polytetrafluoroethylene (PTFE), a fluoropolymer known for its near-universal chemical inertness, the hose withstands exposure to aggressive reagents, including strong acids, bases, solvents, and fuels. Its molecular structure, characterized by strong carbon-fluorine bonds, provides a low coefficient of friction (0.05–0.10) and a smooth inner surface (Ra < 0.2 μm), minimizing flow resistance and ensuring pressure drops below 0.1 bar/m for air at 6 bar.

Functionally, the hose serves as a conduit for gases, liquids, and chemicals in demanding environments. It supports working pressures of 7–25 kg/cm² and burst pressures up to 100 kg/cm², depending on size, making it suitable for both low- and high-pressure systems. The hose’s flexibility, with minimum bend radii ranging from 15 mm for smaller sizes to 100 mm for larger ones, allows routing in complex systems without kinking, though it is less flexible than polyurethane or nylon hoses due to PTFE’s inherent rigidity.

The hose’s thermal performance is exceptional, with service temperatures ranging from -65°C to 260°C for air, -65°C to 200°C for oils, and 0°C to 150°C for water. Its dielectric strength of ~60 kV/mm ensures excellent electrical insulation, making it ideal for applications involving high-voltage equipment or sensitive electronics. The hose’s chemical inertness prevents degradation from exposure to corrosive media, with no significant change in properties after 168 hours in concentrated acids (e.g., sulfuric acid) at 20°C.

Manufactured via paste extrusion, the hose achieves uniform wall thickness (±0.05 mm) and precise dimensions for compatibility with standard fittings, such as stainless steel compression or push-to-connect fittings. Its lightweight design—ranging from 20 g/m for JT0402 to 150 g/m for JT2018—facilitates handling and reduces system weight. Optional PFA construction, which offers similar chemical resistance but improved flexibility and clarity, can be specified for specialized applications.

The PTFE hose complies with RoHS, REACH, and FDA 21 CFR 177.1550 standards for food-grade applications, ensuring safety in chemical and food processing. Its low moisture absorption (<0.01% by weight) prevents dimensional changes, and its UV resistance (per ISO 4892-2) ensures minimal degradation after 2,000 hours of exposure, making it suitable for both indoor and outdoor use.

Specifications and Dimensions

The Teflon PTFE Hose is available in a range of sizes to meet diverse application requirements. Below is a detailed table of key specifications for common product codes.

| Product Code | Outer Diameter (mm) | Inner Diameter (mm) | Wall Thickness (mm) | Weight (g/m) | Minimum Bend Radius (mm) | Working Pressure at 20°C (kg/cm²) | Burst Pressure at 20°C (kg/cm²) |

|---|---|---|---|---|---|---|---|

| JT0402 | 4.0 | 2.0 | 1.0 | 20 | 15 | 25 | 100 |

| JT0604 | 6.0 | 4.0 | 1.0 | 30 | 20 | 20 | 80 |

| JT0806 | 8.0 | 6.0 | 1.0 | 40 | 25 | 18 | 72 |

| JT1008 | 10.0 | 8.0 | 1.0 | 50 | 30 | 15 | 60 |

| JT1209 | 12.0 | 9.0 | 1.5 | 70 | 40 | 12 | 48 |

| JT1613 | 16.0 | 13.0 | 1.5 | 100 | 60 | 10 | 40 |

| JT2018 | 20.0 | 18.0 | 1.0 | 150 | 100 | 7 | 28 |

Additional Specifications:

- Operating Temperature Range:

- Air: -65°C to 260°C

- Oil: -65°C to 200°C

- Water: 0°C to 150°C

- Material: Virgin polytetrafluoroethylene (PTFE); optional PFA construction

- Colors: White (standard), transparent (PFA option)

- Length per Coil: 100 m (standard), custom lengths available

- Pressure Derating: 50% at 150°C, 70% at 200°C (oil/air)

- Compliance: RoHS, REACH, FDA 21 CFR 177.1550

- Dielectric Strength: ~60 kV/mm

- Moisture Absorption: <0.01% by weight

These specifications ensure the PTFE hose meets the needs of high-pressure chemical transfer and low-temperature applications, with precise dimensions enhancing compatibility with fittings.

Materials and Build Quality

The Teflon PTFE Hose is constructed from high-purity virgin polytetrafluoroethylene (PTFE), a fluoropolymer with a density of ~2.2 g/cm³ and a melting point of 327°C. PTFE’s carbon-fluorine bonds provide unmatched chemical inertness, resisting virtually all reagents, including strong acids (e.g., hydrochloric, nitric), bases, solvents, and fuels. The material’s low coefficient of friction (0.05–0.10) and smooth inner surface (Ra < 0.2 μm) minimize flow resistance and prevent particle buildup, critical for chemical and food-grade applications.

The hose’s abrasion resistance is moderate (~50 mg loss per DIN ISO 4649), but its chemical inertness compensates for wear in corrosive environments. PTFE’s near-zero moisture absorption (<0.01% by weight) ensures dimensional stability, with less than 0.2% change in diameter or length under humid conditions. Its UV resistance, tested per ISO 4892-2, shows no significant degradation after 2,000 hours, making it suitable for outdoor use.

Optional PFA construction, with a lower melting point (305°C) and improved flexibility, is available for applications requiring enhanced clarity or reduced stiffness. PFA maintains similar chemical resistance but offers a slightly higher elongation at break (400% vs. PTFE’s ~300%). Both materials are free of plasticizers, ensuring compliance with RoHS, REACH, and FDA standards.

The hose is manufactured via paste extrusion, a process that ensures uniform wall thickness (±0.05 mm) and consistent inner/outer diameter ratios. Rigorous testing validates durability:

- Pressure Testing: Burst pressure exceeds 4x working pressure at 20°C.

- Thermal Cycling: No cracking after 1,000 cycles between -65°C and 200°C.

- Chemical Exposure: No degradation after 168 hours in concentrated acids or fuels.

The PTFE hose’s build quality supports a service life of 10–15 years in typical conditions, with minimal maintenance required due to its chemical and thermal stability.

Key Features

Maximum Chemical Inertness

- Resists virtually all chemicals, including strong acids, bases, and solvents, ensuring reliability in aggressive environments.

Oil and Fuel Resistance

- Withstands exposure to petroleum-based oils, fuels, and corrosive chemicals without degradation.

Superior Electrical Insulation

- Dielectric strength of ~60 kV/mm supports applications requiring high electrical insulation.

Wide Temperature Range

- Operates from -65°C to 260°C (media-dependent), ideal for extreme environments.

Low Friction Surface

- Smooth inner surface (Ra < 0.2 μm) minimizes flow resistance and particle buildup.

Lightweight Design

- Weights from 20 g/m to 150 g/m reduce system load and installation effort.

Compatibility with Fittings

- Precise dimensions ensure seamless integration with compression and push-to-connect fittings.

Long Service Life

- Chemical and thermal stability support a 10–15-year lifespan in demanding conditions.

These features make the PTFE hose a robust solution for chemical, thermal, and electrical applications.

Use Cases / Applications

The Teflon PTFE Hose’s unique properties support a wide range of demanding applications.

- Chemical Transfer: Conveys aggressive chemicals (e.g., acids, solvents) in processing plants. The JT0402 model is ideal for precision dosing, while JT2018 handles high-volume transfer.

- Fuel and Oil Handling: Used in automotive and aerospace fuel lines, with oil resistance ensuring reliability in engine compartments. The JT0806 model balances flow and flexibility.

- Insulated Fluid Lines: Provides electrical insulation in high-voltage systems, such as semiconductor manufacturing or medical equipment, with JT0604 suited for compact setups.

- Food and Beverage Processing: FDA-compliant variants transport food-grade liquids, with smooth surfaces preventing contamination. The JT1209 model supports moderate flows.

- Aerospace and Defense: Used in hydraulic and pneumatic systems for aircraft, withstanding extreme temperatures and fuels. The JT1613 model handles high-pressure fluids.

- Pharmaceutical Manufacturing: Conveys sterile fluids or gases, with chemical inertness ensuring purity. Transparent PFA variants allow visual monitoring.

- Industrial Automation: Supports pneumatic and hydraulic lines in robotics, with PTFE’s low friction reducing wear on fittings.

Engineers can calculate flow rates using the Hagen-Poiseuille equation for liquids or Darcy-Weisbach for gases, ensuring optimal sizing. The hose’s compatibility with IoT sensors enables real-time monitoring of pressure and temperature.

Comparison

Below is a comparison of the Teflon PTFE Hose with PU, nylon, and braided PU hoses.

| Feature | PTFE Hose | PU Soft Hose | Nylon Hose | Braided PU Hose |

|---|---|---|---|---|

| Flexibility (Bend Radius) | 15–100 mm | 8–15 mm | 10–100 mm | 39–66 mm |

| Working Pressure (kg/cm²) | 7–25 | 6–8 | 12–25 | 8–10 |

| Chemical Resistance | Virtually all chemicals | Oils, detergents | Oils, acids, alkalis | Oils, detergents |

| Temperature Range (°C) | -65 to 260 | -30 to 60 | -40 to 80 | -20 to 60 |

| Weight (g/m, Ø10 mm) | 50 | 35 | 35 | 60 |

| Electrical Insulation | Excellent (~60 kV/mm) | Moderate (~20 kV/mm) | Moderate (~18 kV/mm) | Moderate (~20 kV/mm) |

| Cost per Meter ($) | 3.0–6.0 | 1.8–3.2 | 1.0–2.5 | 2.0–3.5 |

The PTFE hose excels in chemical resistance, temperature range, and electrical insulation, outperforming PU, nylon, and braided PU hoses in harsh environments. However, it is less flexible and more expensive, requiring careful application matching.

Benefits and Limitations

Benefits:

- Unmatched Chemical Resistance: Handles virtually all chemicals, ideal for aggressive media.

- Wide Temperature Capability: Supports extreme conditions from -65°C to 260°C.

- Superior Electrical Insulation: Ensures safety in high-voltage applications.

- Long Service Life: 10–15 years with minimal degradation.

- Low Maintenance: Chemical inertness reduces cleaning and replacement needs.

Limitations:

- Lower Flexibility: Larger bend radii compared to PU soft hoses limit use in tight spaces.

- Higher Cost: More expensive than PU or nylon due to PTFE’s premium properties.

- Water Temperature Limit: Restricted to 150°C for water, less than for air or oil.

- Moderate Abrasion Resistance: Less durable in high-wear environments compared to braided PU.

The PTFE hose’s benefits make it ideal for chemical and high-temperature applications, though its cost and flexibility limitations require careful consideration.

Maintenance or Care Guide

To maximize the PTFE hose’s lifespan:

- Inspection: Check monthly for abrasions or cracks. Replace if damage exceeds 5% of wall thickness.

- Cleaning: Use mild detergents or water; avoid mechanical scrubbing to preserve the smooth surface.

- Pressure Monitoring: Use gauges to stay within rated limits (7–25 kg/cm²), preventing overpressure.

- Storage: Store coils flat in dry, shaded areas below 30°C to prevent deformation.

- Fitting Checks: Tighten stainless steel fittings to 2–3 Nm every 6 months to prevent leaks.

- Chemical Compatibility: Confirm compatibility with specific chemicals via manufacturer data.

Regular maintenance ensures a service life of 10–15 years, with minimal performance degradation.

Conclusion

The Teflon PTFE Hose is a premier solution for demanding chemical, thermal, and electrical applications, offering unmatched resistance to aggressive media, wide temperature capability, and superior insulation. Its robust construction and long service life make it ideal for chemical transfer, fuel handling, and insulated fluid lines in industries like aerospace, pharmaceuticals, and automation. While its flexibility and cost present challenges, the PTFE hose’s technical excellence ensures reliability and safety in the most demanding environments, driving efficiency and innovation.

Tiếng Việt

Tiếng Việt

![폴리우레탄연질호스 [PU Soft Hose]](https://yongshan.asia/wp-content/uploads/2025/09/6_3f56f14307e6c553a5d230d14dc10d78-100x100.png)

![폴리우레탄연질호스 [PU Soft Hose]](https://yongshan.asia/wp-content/uploads/2025/09/6_3f56f14307e6c553a5d230d14dc10d78-300x300.png)

Reviews

There are no reviews yet.