Nylon Hose for Pneumatic and Fluid Conveyance Systems: A Comprehensive Technical Guide

Introduction

In the realm of industrial automation, fluid transfer, and pneumatic systems, the demand for versatile, durable, and high-performance tubing solutions is ever-growing. The Nylon Hose (NA) stands out as a multipurpose tubing solution engineered for pneumatic systems and the conveyance of water, oil, and a wide range of chemical fluids. Crafted from high-quality nylon (polyamide), this hose combines lightweight construction, excellent flexibility, and robust resistance to internal pressure, vibration, corrosion, heat, and chemical attack. These attributes enhance ease of installation and ensure long-term reliability in demanding environments.

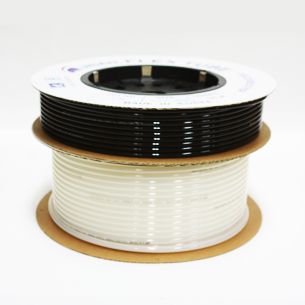

The NA hose is rated for continuous operation from -40°C to 80°C, offering superior weathering and flex-fatigue performance. Available in a variety of metric and imperial sizes—ranging from 4×2 mm to 16×13 mm and 1/4″ to 1/2″ variants—it caters to diverse applications. With wall thicknesses between 0.75 mm and 1.57 mm, burst pressures from 35 to 150 kg/cm² at 20°C, and minimum bend radii from 10 mm to 100 mm, the NA hose is designed for flexibility and strength. Its lightweight design (9–70 g/m) and availability in black and white colors further enhance its practicality for industrial use.

This article provides a detailed technical exploration of the NA nylon hose, covering its specifications, materials, key features, applications, comparisons, benefits, limitations, and maintenance guidelines. Aimed at engineers, system designers, and technical professionals, this guide offers in-depth insights into how the NA hose meets the needs of modern industrial systems, from pneumatic controls to chemical fluid transfer. As industries prioritize efficiency, durability, and adaptability, the NA hose emerges as a critical component in achieving reliable and sustainable operations.

Technical Overview

The Nylon Hose (NA) is a high-performance tubing solution designed for dynamic and static applications requiring robust mechanical and chemical properties. Manufactured from polyamide 6 (PA6) or polyamide 12 (PA12), depending on the model, the hose offers a tensile strength of approximately 45–60 MPa and an elongation at break of 200–300%, ensuring durability under mechanical stress. Its molecular structure provides a balance of rigidity and flexibility, making it suitable for both high-pressure pneumatic systems and low-pressure fluid conveyance.

Functionally, the NA hose serves as a conduit for compressed air, water, oils, and various chemical fluids, including dilute acids and alkalis (pH 4–10). Its smooth inner surface, with a roughness average (Ra) of less than 0.3 μm, minimizes flow resistance, achieving pressure drops below 0.15 bar/m for air at 6 bar. The hose’s low moisture absorption (1–2% by weight for PA6, <1% for PA12) ensures dimensional stability, with less than 1.5% change in diameter or length in humid conditions.

The hose is produced through precision extrusion, ensuring uniform wall thickness (±0.05 mm) and compatibility with standard fittings, such as push-to-connect, barbed, or compression connectors. Its flexibility, with minimum bend radii ranging from 10 mm for smaller sizes to 100 mm for larger ones, allows it to navigate complex routing without kinking, a critical advantage over stiffer materials like metal or rigid PVC.

Thermally, the NA hose operates reliably from -40°C to 80°C, with short-term tolerance up to 100°C. Its chemical resistance extends to petroleum-based oils, lubricants, and certain solvents, making it suitable for automotive, manufacturing, and chemical processing applications. Electrically, the hose is non-conductive, with a dielectric strength of approximately 18 kV/mm, reducing risks in systems with electrical components.

The lightweight design—ranging from 9 g/m for 4×2 mm to 70 g/m for 16×13 mm—facilitates handling and reduces system weight. Available in black and white, the hose supports basic line identification, though its color range is more limited than some alternatives. The NA hose’s technical design ensures a robust solution for applications requiring flexibility, strength, and chemical resistance, making it a staple in industrial pneumatic and fluid systems.

Specifications and Dimensions

The NA nylon hose is available in a range of metric and imperial sizes to accommodate various system requirements. Below is a detailed table of key specifications for common product codes.

| Product Code | Outer Diameter (mm/in) | Inner Diameter (mm/in) | Wall Thickness (mm) | Weight (g/m) | Minimum Bend Radius (mm) | Working Pressure at 20°C (kg/cm²) | Burst Pressure at 20°C (kg/cm²) |

|---|---|---|---|---|---|---|---|

| NA-4X2 | 4.0 mm | 2.0 mm | 1.0 | 9 | 10 | 25 | 75 |

| NA-6X4 | 6.0 mm | 4.0 mm | 1.0 | 15 | 15 | 25 | 75 |

| NA-8X6 | 8.0 mm | 6.0 mm | 1.0 | 22 | 20 | 20 | 60 |

| NA-10X7.5 | 10.0 mm | 7.5 mm | 1.25 | 35 | 30 | 18 | 54 |

| NA-12X9 | 12.0 mm | 9.0 mm | 1.5 | 50 | 40 | 15 | 45 |

| NA-16X13 | 16.0 mm | 13.0 mm | 1.5 | 70 | 100 | 12 | 36 |

| NA-1/4 | 6.35 mm (1/4″) | 4.57 mm (0.18″) | 0.89 | 12 | 12 | 25 | 75 |

| NA-3/8 | 9.53 mm (3/8″) | 6.99 mm (0.275″) | 1.27 | 30 | 25 | 20 | 60 |

| NA-1/2 | 12.70 mm (1/2″) | 9.56 mm (0.376″) | 1.57 | 45 | 35 | 15 | 45 |

Additional Specifications:

- Operating Temperature Range: -40°C to 80°C

- Material: Polyamide 6 (PA6) or Polyamide 12 (PA12)

- Colors: Black, white

- Length per Coil: Standard 100 m, custom lengths available

- Pressure Derating: 50% at 60°C, 70% at 80°C

- Compliance: RoHS, REACH; food-grade variants meet FDA 21 CFR 177.1500

These specifications ensure the NA hose meets diverse application needs, with smaller sizes (e.g., NA-4X2) ideal for precision pneumatics and larger sizes (e.g., NA-16X13) suited for high-flow fluid transfer. The lightweight design and precise dimensions enhance compatibility with standard fittings.

Materials and Build Quality

The NA hose is manufactured from high-grade polyamide (nylon), typically PA6 or PA12, depending on the application. PA6 offers higher tensile strength (up to 60 MPa) and cost-effectiveness, while PA12 provides superior chemical resistance and lower moisture absorption (<1% by weight). Both materials exhibit a Shore D hardness of 60–70, balancing flexibility with rigidity for structural integrity.

The hose’s abrasion resistance, measured at less than 40 mg per DIN ISO 4649, ensures durability in environments with mechanical wear, such as robotic systems or conveyor lines. Its chemical resistance includes compatibility with petroleum-based oils, greases, and dilute acids/alkalis (pH 4–10), with no significant degradation after 168 hours of exposure at 20°C. Weathering performance, tested per ISO 4892-2, shows minimal loss of mechanical properties after 1,000 hours of UV exposure, though black variants outperform white in prolonged outdoor use.

The extrusion process ensures uniform wall thickness (±0.05 mm) and a smooth inner surface (Ra < 0.3 μm), reducing flow resistance and preventing particle accumulation in fluid applications. The hose is free of plasticizers, minimizing leaching risks, and complies with RoHS and REACH regulations. For food-grade applications, PA12 variants meet FDA standards.

Rigorous testing validates the hose’s durability:

- Flexural Fatigue: Over 500,000 cycles at minimum bend radius without failure.

- Pressure Testing: Burst pressure exceeds 3x working pressure at 20°C.

- Thermal Cycling: No cracking after 500 cycles between -40°C and 80°C.

The materials and manufacturing precision contribute to a service life of 8–12 years in typical industrial conditions, with PA12 offering slightly longer durability in chemical-heavy environments.

Key Features

High Pressure Capability

- Supports working pressures up to 25 kg/cm² (355 psi) at 20°C, ideal for high-pressure pneumatic systems.

Excellent Flexibility

- Minimum bend radii from 10 mm to 100 mm allow routing in tight spaces without kinking.

Lightweight Design

- Weights from 9 g/m to 70 g/m reduce installation effort and system load.

Chemical and Corrosion Resistance

- Resists oils, greases, and dilute acids/alkalis, ensuring reliability in harsh environments.

Wide Temperature Range

- Operates from -40°C to 80°C, suitable for extreme cold and moderate heat applications.

Superior Weathering

- Maintains performance after prolonged UV exposure, ideal for outdoor use (especially black variants).

Compatibility with Standard Fittings

- Precise dimensions ensure seamless integration with push-to-connect and compression fittings.

Long-Term Reliability

- Flex-fatigue resistance and low moisture uptake support a service life of 8–12 years.

These features position the NA hose as a robust and versatile solution for industrial applications requiring durability and flexibility.

Use Cases / Applications

The NA nylon hose supports a wide range of applications due to its strength, flexibility, and chemical resistance.

- Pneumatic Systems: Powers actuators, valves, and grippers in automation, such as in automotive assembly or semiconductor manufacturing. Smaller sizes (e.g., NA-4X2) are ideal for precision pneumatics.

- Fluid Conveyance: Transports water, oils, and non-corrosive chemicals in processing plants. Food-grade PA12 variants are used in beverage and food processing, meeting FDA standards.

- Automotive Applications: Supplies air to pneumatic tools and robotic arms in manufacturing lines. The hose’s abrasion resistance suits dynamic connections.

- Industrial Automation: Used in robotics and conveyor systems for air and fluid delivery. The NA-8X6 size balances flow and flexibility in compact setups.

- Marine and Outdoor Systems: Resists corrosion in marine pneumatics or outdoor irrigation systems, with black hoses preferred for UV exposure.

- Medical and Laboratory Equipment: Delivers compressed air or gases in devices like ventilators or analytical instruments, with PA12 ensuring chemical compatibility.

- Construction and Mining: Powers pneumatic drills and tools, with larger sizes (e.g., NA-16X13) supporting high-volume air delivery.

Engineers can calculate flow rates using the Darcy-Weisbach equation for gases or Hagen-Poiseuille for liquids, ensuring optimal sizing. The hose’s compatibility with IoT sensors enables real-time monitoring, enhancing system reliability.

Comparison

Below is a comparison of the NA nylon hose with polyurethane (PU) and PVC hoses.

| Feature | Nylon Hose (NA) | PU Hose | PVC Hose |

|---|---|---|---|

| Flexibility (Bend Radius) | 10–100 mm | 10–40 mm | 30–80 mm |

| Working Pressure (kg/cm²) | 12–25 | 7–10 | 5–8 |

| Chemical Resistance | Oils, acids, alkalis | Oils, acids, alkalis | Moderate |

| Weight (g/m, Ø8 mm) | 22 | 50 | 70 |

| UV Resistance | Moderate (black better) | Excellent | Poor |

| Moisture Uptake | 1–2% (PA6), <1% (PA12) | <0.5% | 0.8–1.5% |

| Abrasion Resistance | Moderate | High | Low |

| Cost per Meter ($) | 1.0–2.5 | 1.5–3.0 | 0.8–2.0 |

The NA hose excels in high-pressure applications and low-temperature performance, outperforming PU in pressure capacity and PVC in durability. However, PU offers better flexibility and UV resistance, while PVC is more cost-effective but less durable.

Benefits and Limitations

Benefits:

- High Pressure Capability: Supports up to 25 kg/cm², ideal for demanding pneumatic systems.

- Wide Temperature Range: Operates from -40°C to 80°C, suitable for extreme conditions.

- Lightweight Design: Reduces installation effort and system weight.

- Chemical Resistance: Ensures reliability in oil, grease, and chemical environments.

- Long Service Life: 8–12 years with minimal degradation in typical conditions.

Limitations:

- Limited Color Options: Only black and white, reducing line identification versatility.

- Moisture Absorption: Higher than PU for PA6, potentially affecting performance in humid environments.

- Flexibility: Less flexible than PU in tight spaces, with larger bend radii for bigger sizes.

- UV Resistance: Moderate for white variants, requiring UV protection for prolonged outdoor use.

The NA hose’s benefits make it a strong choice for high-pressure and low-temperature applications, though its limitations require careful consideration in humid or UV-heavy environments.

Maintenance or Care Guide

To maximize the NA hose’s lifespan:

- Inspection: Check monthly for abrasions, cuts, or kinks. Replace if damage exceeds 10% of wall thickness.

- Cleaning: Use mild soap and water; avoid solvents that degrade nylon.

- Pressure Monitoring: Use gauges to stay within rated limits, preventing overpressure.

- Storage: Store coils flat in dry, shaded areas below 30°C to prevent deformation.

- Fitting Checks: Tighten fittings to 2–3 Nm every 6 months to prevent leaks.

- UV Protection: Apply UV-resistant wraps for white hoses in outdoor applications exceeding 1 year.

Regular maintenance ensures a service life of 8–12 years, with minimal performance degradation.

Conclusion

The Nylon Hose (NA) is a versatile and durable solution for pneumatic and fluid conveyance systems, offering high pressure capability, chemical resistance, and a wide temperature range. Its technical specifications and robust materials make it ideal for industries from automotive to medical, driving efficiency and reliability. While it has limitations in flexibility and UV resistance compared to polyurethane, its performance in high-pressure and low-temperature environments makes it a valuable asset for modern industrial applications.

Tiếng Việt

Tiếng Việt

![폴리우레탄연질호스 [PU Soft Hose]](https://yongshan.asia/wp-content/uploads/2025/09/6_3f56f14307e6c553a5d230d14dc10d78-300x300.png)

Reviews

There are no reviews yet.