Air Hose Reel — Technical Overview, Specifications, Applications and Maintenance Guide

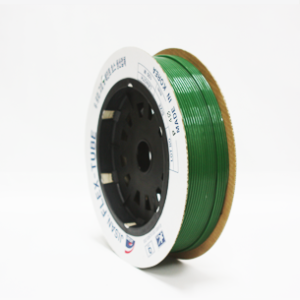

The Air Hose Reel is a compact, lightweight, retractable hose assembly engineered to supply compressed air reliably across painting, construction, automotive and general industrial air-tool applications. Combining high elasticity with robust resistance to cold, oil and water exposure, this product is intended for demanding shop-floor environments and service departments where reach, rapid retraction, hose protection and dependable pressure delivery are essential.

Introduction

Compressed air remains one of the most ubiquitous utilities in modern manufacturing, maintenance and automotive repair. An effective supply system must balance workplace ergonomics, hose protection, pressure stability and long-term reliability. The Air Hose Reel is designed to address these needs: it stores and protects air hose when not in use, reduces workplace tripping hazards, simplifies tool mobility and preserves hose service life by preventing excessive bending and abrasion.

This article provides a comprehensive technical treatment of the Air Hose Reel product family: detailed specifications, materials and build quality, installation and maintenance guidance, use cases across industries, comparisons to alternative hose management solutions, and balanced assessments of benefits and limitations for technical decision-makers.

Technical Overview

At its core, an air hose reel integrates a flexible pneumatic hose with a spring-driven or counterbalanced spool, a swivel joint and a housing or frame. The Air Hose Reel models presented here (AR-810N, AR-815N, AR-820N and AR-830N) are spring-retractable reels that provide controlled retraction and storage for polyurethane-based air hose with an internal diameter of 8 mm and an outer diameter of 12 mm.

Key functional components:

- Hose — High-elasticity, oil- and water-resistant polymer hose with nominal 8 mm inner diameter (ID) and 12 mm outer diameter (OD).

- Spool and spring mechanism — Heavy-gauge, tempered-steel torsion spring encased in a corrosion-resistant reel housing that provides powered retraction and controlled payout.

- Swivel joint — Sealed multi-lip swivel assembly that allows the hose spool to rotate while maintaining an airtight connection to the inlet port.

- Mounting bracket — Adjustable mounting plate for wall, ceiling or bench installation; typically powder-coated steel to resist workshop environments.

- Stop mechanism — Ratchet or indexed stop to allow the hose to lock at the user-selected length during operations.

Designed for continuous operation within an ambient temperature range of -20°C to 60°C, these reels deliver a maximum recommended working pressure of 15 kgf/cm² (approx. 14.7 bar or 213 psi). The hose formulation and nominal bending radius meet the requirement of a minimum bending radius equal to six times the hose ID (≥ 6 × 8 mm = 48 mm), ensuring consistent airflow and preventing premature fatigue.

Specifications and Dimensions

The following table summarizes the technical specifications for the standard product variants in the Air Hose Reel family.

| Model | Hose OD × ID (mm) | Hose Length (m) | Maximum Working Pressure | Burst Pressure (typ.) | Minimum Bending Radius | Reel Weight (kg) | Recommended Mounting Fasteners |

|---|---|---|---|---|---|---|---|

| AR-810N | 12 × 8 | 10 | 15 kgf/cm² (≈14.7 bar / 213 psi) | 45 kgf/cm² (≈44.0 bar / 638 psi) | ≥ 48 mm | 6.7 | M8 × 2 / M10 × 2 (grade 8.8 or higher) |

| AR-815N | 12 × 8 | 15 | 15 kgf/cm² (≈14.7 bar / 213 psi) | 45 kgf/cm² (≈44.0 bar / 638 psi) | ≥ 48 mm | 7.5 | M8 × 2 / M10 × 2 (grade 8.8 or higher) |

| AR-820N | 12 × 8 | 20 | 15 kgf/cm² (≈14.7 bar / 213 psi) | 45 kgf/cm² (≈44.0 bar / 638 psi) | ≥ 48 mm | 8.0 | M8 × 2 / M10 × 2 (grade 8.8 or higher) |

| AR-830N | 12 × 8 | 30 | 15 kgf/cm² (≈14.7 bar / 213 psi) | 45 kgf/cm² (≈44.0 bar / 638 psi) | ≥ 48 mm | 8.7 | M8 × 2 / M10 × 2 (grade 8.8 or higher) |

Notes:

- Working pressure is the maximum sustained pressure recommended during normal operation. Burst pressures are measured under controlled laboratory conditions and include safety margin; local regulations and standards should be consulted for in-field pressure testing.

- Weights are nominal and include hose, reel mechanism and mounting bracket but exclude fittings and couplers.

Materials and Build Quality

A robust materials selection and high-quality manufacturing processes are critical to long service life in industrial hose reels. The Air Hose Reel models employ materials optimized for mechanical strength, chemical resistance and wear performance:

- Hose material: The hose is manufactured from a polyurethane-based elastomer blended with proprietary additives to increase oil and water resistance while retaining high elasticity and low-temperature flexibility. Polyurethane hoses combine high tensile strength, abrasion resistance and good “memory” (ability to return to original shape) — ideal for retractable reels where the hose is repeatedly coiled.

- Reel housing: Die-formed, powder-coated steel provides a corrosion-resistant exterior finish. Powder coating delivers superior adhesion and chemical resistance compared to conventional paints, which is important in paint booths and repair shops where solvents are present.

- Internal spring: Hardened and tempered alloy steel spring designed for extended cycle life. Springs are shot-peened and heat-treated to improve fatigue resistance; the design includes a secure anchoring system to prevent despooling during heavy use.

- Swivel assembly: Precision-machined brass swivel with PTFE or nitrile seals ensures a leak-free interface between the fixed inlet and rotating spool. Brass is chosen for corrosion resistance and machinability; PTFE/nitrile sealing offers low friction and durability at operating temperatures.

- Fittings and couplers: Standard fittings are zinc-plated or nickel-plated steel with optional stainless-steel or brass choices for corrosive environments. Quick-connect couplers conform to ISO or national standards as required by the end user.

Manufacturing tolerances, nondestructive testing of springs and pressure testing of finished reels are standard quality control steps. Cycle testing (retraction/payout) in production assesses spring performance and swivel seal durability; typical acceptance criteria include leak-free operation at working pressure for a specified minimum number of cycles (often >10,000 cycles for industrial reels).

Key Features

The Air Hose Reel family integrates many features that support efficient, safe and durable pneumatic distribution:

- Retractable spring mechanism — Controlled retraction keeps the hose taut and minimizes floor hazards. The spring is optimized to retract the hose smoothly even at full length.

- Compact, lightweight design — Low mass for wall-mounted or mobile deployment without compromising durability.

- Cold-flexible hose compound — Rated functional down to -20°C, enabling outdoor use in temperate winter conditions without significant loss of flexibility.

- Oil and water resistance — Formulation resists degradation from incidental oil exposure and water ingress common in auto shops and industrial environments.

- Indexed stop positions — Positive locking positions allow the hose to be secured at selected lengths during operation.

- Swivel inlet with low-torque seals — Smooth payout and minimal torque on the spool to reduce operator fatigue and wear on the inlet port.

- Multiple lengths — Models with 10 m, 15 m, 20 m and 30 m hose lengths to match workspace layout and expected tool reach.

- Standard mounting options — Wall, ceiling or bench mounting with an adjustable bracket angle to direct the reel payout path.

- Serviceability — Replaceable hose and modular spring assembly reduce lifecycle maintenance costs.

Use Cases and Applications

The Air Hose Reel is engineered for broad adoption across trade shops, production lines and maintenance facilities. Typical applications include:

Painting and Spray Finishing

- Supply to spray guns in localized paint booths or mobile spray carts.

- Maintains clean hose routing and prevents hose contact with painted surfaces.

- Retractable storage reduces overspray fouling and reduces the need for manual hose handling.

Automotive Repair and Bodywork

- Connection to impact wrenches, ratchets, air sanders and other pneumatic tools.

- Resists oil droplets and low-temperature exposure in garage environments.

- Improves ergonomics during wheel removal, chassis servicing and paint touch-up operations.

Construction, Woodworking and Finish Carpentry

- Feeding finish nailers, staplers, pneumatic rollers and small grinders.

- Durable hose material stands up to abrasive jobsite conditions.

General Factory and Maintenance Tasks

- Supplying air to test benches, leak-testing jig fixtures and pneumatic actuators in repetitive maintenance programs.

- Useful in assembly lines where tools are shared across stations and need rapid reconnection.

Mobile Service Units and Fleet Maintenance

- Compact reels fit into service vans and mobile carts; retractability reduces the footprint and prevents tangles while driving.

Comparison with Alternative Solutions

Selecting the right hose management system depends on parameters such as hose length, working pressure, operating environment, budget and installation constraints. The table below compares the Air Hose Reel family (spring-retractable polyurethane hose reels) against alternative approaches: open (free) hose, rubber hose with reel, motorized reels and coil hoses.

| Attribute | Air Hose Reel (AR-series) | Open/Free Hose | Rubber Hose on Reel | Motorized Reel | Coil Hose |

|---|---|---|---|---|---|

| Retractability | Automatic spring retract; indexed stop | None; manual coil required | Manual or spring (if equipped) | Powered retract; high torque for long hoses | Self-coiling; limited length |

| Portability | High (lightweight) | High (but bulky when stored) | Moderate (rubber heavier) | Low (requires power and heavier housing) | High but short reach |

| Cold flexibility | Good to -20°C | Depends on hose material | Rubber can stiffen at low temps | Depends on hose | Poor for cold conditions |

| Oil / water resistance | High (polyurethane blend) | Varies | Good (depending on formulation) | Varies | Limited |

| Serviceability | High (replaceable hose & spring) | High (hose replacement simple) | Moderate (heavier components) | Lower (complex electrical/mechanical parts) | Low (integrated coil) |

| Cost | Moderate (balanced) | Low (hose only) | Moderate to high | High (motor & control) | Low to moderate |

| Best for | Workshops, paint booths, service bays | Large fixed runs, temporary use | Heavy-duty shop use | Long-run automated systems | Light-duty handheld tools with short reach |

Summary: The AR-series retractable reels strike a balance between durability, cold performance and price. They outperform coil hoses in reach and cold flexibility, are lighter and easier to deploy than rubber hoses, and offer a lower-cost, simpler solution than motorized reels for workshop and bay applications.

Benefits and Limitations

Benefits

- Improved ergonomics and safety — Retracted hoses reduce tripping hazards and workplace clutter, improving operator safety and workflow efficiency.

- Hose protection — Housing and controlled retraction reduce abrasion, kinking and UV exposure that accelerate hose failure.

- Consistent pressure delivery — Proper hose sizing maintains low pressure drop over the hose length and consistent tool performance.

- Durability in varied environments — Polyurethane blend resists oil and water, and the housing protects internal components from incidental impact and contamination.

- Flexible installation — Wall, ceiling and bench mounting options allow adaptation to different workshop layouts.

- Serviceability — Replaceable hoses, seals and spring modules reduce total cost of ownership.

Limitations

- Working pressure limit — The specified maximum working pressure of 15 kgf/cm² (≈14.7 bar / 213 psi) is suitable for most handheld pneumatic tools but may be below requirements for specialized high-pressure systems.

- Length vs. pressure drop — Longer hoses (20–30 m) increase pressure drop and may reduce tool performance unless supply pressure is adjusted or compressor capacity is adequate.

- Spring fatigue — Although designed for extended cycles, springs are mechanical components subject to fatigue and eventual replacement; heavy industrial duty cycles may shorten expected life.

- Chemical limitations — The hose compound resists oils and water but can be degraded by some aggressive solvents, strong acids or chlorinated hydrocarbons commonly used in specialized cleaning or stripping operations.

- Temperature extremes — Rated down to -20°C and up to 60°C; above or below these limits hose stiffness, seal integrity and spring behavior may be compromised.

Installation and Mounting Guidance

Correct installation ensures safe operation, minimizes premature wear and preserves the specified working pressure and cycle life. The following recommendations are targeted at technical installers and maintenance personnel.

Mounting Location and Orientation

- Choose a rigid mounting surface (concrete wall, structural steel, heavy bench) capable of supporting static and dynamic loads. Typical reel weights are listed in the specifications table; dynamic loading from rapid retraction or tool tugging should be accounted for.

- Install the reel at a height and lateral position that minimizes hose contact with the floor and painted surfaces; for spray finishing, position the reel so the payout direction follows the operator’s natural motion.

- Choose orientation (horizontal or vertical) according to model options. If the reel will be ceiling-mounted, ensure the bracket supports are rated for the increased leverage from the suspended load.

Fasteners and Torque

- Use the recommended fastener sizes (M8 or M10 graded bolts) with appropriate washers and locking nuts. For concrete mounts use anchors rated for the required tensile and shear loads.

- Tightening torque: M8 bolts — 20–25 N·m; M10 bolts — 40–45 N·m. Consult anchor manufacturer data for torque limits when using concrete anchors.

Inlet Connection and Supply Requirements

- Supply pressure should be controlled and regulated upstream of the reel to avoid pulses or pressures above the rated 15 kgf/cm². Include a pressure relief or safety valve in the supply line per local safety regulations.

- Use an appropriate inlet filter and water trap upstream to reduce contamination and moisture entering the swivel assembly and hose.

Initial Setup and Checks

- Verify mounting fasteners are torqued to specification and the reel is level in the intended orientation.

- Connect the supply using the recommended fittings and check for leaks at working pressure using a soapy-water test or leak detector solution.

- Unwind the hose fully a few times to seat the spring and check for smooth retraction and indexed stops.

- Set the stop positions according to your application requirements.

Maintenance and Care Guide

Routine preventive maintenance extends the life of the reel and helps avoid downtime. Below is a professional maintenance schedule and set of recommended procedures.

Daily / Pre-Shift Checks

- Visual inspection of hose for cuts, abrasions, bulges or kinks.

- Check hose routing for contact with sharp edges or moving equipment.

- Operate the reel through several cycles to ensure smooth payout and retraction.

Weekly Checks

- Inspect swivel joint for signs of leakage or increased rotational torque; slight oiling of external surfaces is acceptable, but internal leaks require seal replacement.

- Verify quick-connect couplers and downstream fittings are secure and free of contamination.

Monthly Maintenance

- Clean the exterior housing and hose with a mild detergent and water. Avoid chlorinated solvents that may attack seals.

- Inspect mounting hardware for loosening; retorque to the specification listed in the installation section if necessary.

- If a lubricated swivel is specified by the manufacturer, replenish lubricant using the recommended grease or oil type.

Annual or 12-Month Service

- Pressure-test the hose assembly at 1.5× working pressure (per applicable safety standards) to verify integrity. Release pressure slowly and inspect for leaks or bulges.

- Inspect internal spring tension and consult the manufacturer’s service bulletin for spring replacement intervals; heavy-use installations may require spring replacement every 1–3 years depending on cycle counts.

- Replace swivel seals and check the condition of the inlet swivel seat; replace hardware that shows significant corrosion or wear.

Hose Replacement Procedure (High-Level)

- Depressurize the system and disconnect the inlet supply.

- Fully retract the hose to expose the spool and hose clamp.

- Loosen and remove the hose clamp or coupling at the spool connection.

- Feed the replacement hose through the guide and attach securely to the spool using the recommended method (crimp, clamp or threaded adapter).

- Perform a functional test at low pressure, then a leak test at normal working pressure.

Operational Best Practices and Troubleshooting

Best Practices

- Avoid sharp bends near fittings by maintaining the minimum bending radius (≥ 48 mm). Repeated bending below this value accelerates wall fatigue and can lead to microcracking.

- When operating tools, avoid applying excessive lateral force to the hose that would place undue strain on the swivel joint or mounting bracket.

- Routinely drain condensate at the compressor and use inline filtration to reduce moisture- and particulate-induced internal wear.

Troubleshooting Common Issues

The table below summarizes common symptoms, probable causes and corrective actions.

| Symptom | Probable Cause | Corrective Action |

|---|---|---|

| Hose does not retract fully | Spring tension reduced or internal locking mechanism engaged | Inspect/replace spring module; verify stop mechanism position and release ratchet if engaged |

| Air leakage at swivel | Worn seal or damaged swivel seat | Replace swivel seals; if seat damaged, replace swivel assembly |

| Excessive pressure drop at tool | Long hose length, narrow ID, blocked filter or compressor insufficient | Use shorter hose or larger bore hose; service filters; verify compressor output and piping |

| Hose showing surface cracking | Chemical attack, UV exposure, or thermal degradation | Replace hose with appropriate chemical-resistant material; relocate reel away from direct sunlight or high heat sources |

Design Considerations for System Integration

When integrating the Air Hose Reel into a larger compressed air distribution network or in a specialized environment, some technical considerations will improve performance and longevity:

- Supply capacity — Ensure the compressor and main distribution can deliver adequate flow (L/min or CFM) at the required pressure for the most demanding concurrent tool usage. For example, high-capacity impact wrenches may demand peak flows that exceed the reel/hose throughput if long hoses create excessive pressure drop.

- Pressure regulation at point of use — Use inline regulators to prevent tool damage and improve repeatability of torque-critical operations.

- Filtration and drying — Install particulate filters and refrigerated or desiccant dryers to limit contamination and moisture ingress that degrade seals and tools.

- Material compatibility — Verify hose compound compatibility if using solvents, paints or specialty chemicals as part of operations; switch to alternative compounds (e.g., nitrile-lined hoses or PTFE-lined assemblies) where required.

Regulatory and Safety Considerations

Always comply with applicable local and national safety standards for compressed air systems. Safety items to consider:

- Pressure-relief valves and overpressure protection per local regulations.

- Lockout/tagout procedures for maintenance and hose replacement operations.

- Personal protective equipment (PPE) when performing pressure tests or working near pressurized equipment.

- Periodic inspections per formal preventive maintenance schedules and recording of maintenance logs for traceability in industrial settings.

Selecting the Right Model

Model selection depends on three principal factors: required reach (hose length), expected duty cycle, and workspace constraints. Use the following guidelines:

- For small service bays and localized tool use, AR-810N (10 m) provides ample reach with minimal weight and lower pressure drop.

- For medium-sized workshops requiring more mobility and staging flexibility, AR-815N (15 m) and AR-820N (20 m) represent a sensible balance between range and pressure drop.

- For overhead distribution or wide-area coverage in assembly or finishing lines, AR-830N (30 m) delivers maximum reach, but be aware of increased pressure drop and potential impact on high-demand pneumatic tools.

When in doubt, measure the distribution layout and confirm the supply compressor’s available flow and pressure at the intended tool location. If tool performance is critical (e.g., torque-critical assembly), perform a pressure-drop calculation or field measurement to ensure tool torque specifications are achievable at the chosen hose length.

Lifecycle Cost and Total Cost of Ownership (TCO)

Lifecycle cost analysis should include initial purchase price, installation, maintenance, spare parts (hose, swivel seals, spring), downtime costs and expected replacement intervals. Highlights:

- The modular design and replaceable components reduce lifecycle costs compared to integrated non-serviceable solutions.

- Reduced tool downtime and faster tool changes due to organized hoses can translate into improved throughput in production settings.

- Preventive maintenance and proper selection of hose length and diameter minimize pressure losses, reducing compressor loading and energy costs.

Environmental Considerations

The materials used in the Air Hose Reel are chosen for durability; however, end-of-life and recycling considerations are increasingly important:

- Steel and brass components are recyclable; separate disassembly of the reel housing and metallic spring facilitates recycling.

- Hose materials (polyurethane blends) should be disposed of per local regulations; some facilities accept used hoses for energy recovery or specialized polymer recycling streams.

- Choose corrosion-resistant finishes and appropriate material options (e.g., stainless steel) for installations in marine or chemically aggressive environments to minimize replacement frequency and environmental impact.

Frequently Asked Questions (Technical)

Q: Can the reel be used outdoors?

A: Yes, the hose and housing materials are resilient to water and limited environmental exposure. Outdoor usage is recommended within the operational temperature range (-20°C to 60°C) and away from prolonged direct UV exposure if possible. If the installation is exposed to harsh weather, consider an optional weatherproof housing or stainless-steel components.

Q: What is the expected service life of the spring mechanism?

A: Service life depends heavily on cycle counts and duty profile. Under moderate workshop use, springs are typically serviceable for several years. For heavy continuous-duty environments with thousands of cycles per week, plan for inspection and potential replacement every 12–24 months. Manufacturers’ cycle-life test data and warranty terms should be reviewed for precise planning.

Q: Are alternative hose materials available?

A: Yes. While polyurethane is specified for these models due to its balance of abrasion resistance and flexibility, alternative constructions such as nitrile-lined hoses for chemical resistance, PTFE-lined hoses for compatibility with aggressive solvents, or rubber compounds for certain heavy-duty applications may be available upon request.

Conclusion

The Air Hose Reel family provides a technically balanced solution for managing compressed air in painting, automotive, construction, woodworking and general industrial settings. With a polyurethane-based hose formulated for oil and water resistance, a robust spring-retract mechanism, and a sealed swivel joint, these reels improve operator safety, reduce hose damage and simplify tool handling across the workshop.

Selecting the right model requires consideration of hose length, tool demand and supply capacity. When installed and maintained according to the recommendations provided here, Air Hose Reels deliver years of reliable performance, low total cost of ownership and ease of integration into compressed-air systems typical of modern production and service environments.

For procurement, system integration or specification assistance, consult with your technical sales representative to confirm compatibility with tool requirements, supply pressure, and environmental conditions.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.