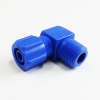

CK Straight: Technical Guide to the Two‑Touch Nut‑Tight Pneumatic Fitting for Compressed‑Air Piping

CK Straight is a two‑touch (nut‑tight) pneumatic tube fitting engineered for compressed‑air distribution on industrial and OEM pneumatic systems. Constructed from durable engineering plastics, the CK Straight offers long service life, superior corrosion and chemical resistance, and robust tube retention under vibration — characteristics that make it ideal for low‑pressure pneumatic control lines, valves, actuators and instrumentation where reliability, compactness and resistance to aggressive environments are required.

Introduction

Pneumatic systems for machine control, material handling, packaging, and instrumentation depend on compact, dependable fittings to maintain leak‑free air distribution and preserve system performance. The CK Straight fitting is designed specifically for these needs. With a two‑touch nut‑tight fastening mechanism, plastic construction for corrosion resistance, and suitability for compressed air and vacuum service at low working pressures, CK Straight addresses a frequent gap between high‑strength metal fittings (which can corrode, be over‑specified and cost more) and push‑to‑connect plastic fittings (which may loosen under vibration).

This article provides a comprehensive technical overview of CK Straight: its functions, specifications, mechanical behavior, applicable materials, installation and maintenance best practices, use cases across industries, comparative evaluation against alternative fittings, and practical guidance for selecting the correct model and ensuring long service life.

Technical Overview

The CK Straight is a nut‑tight straight inline pneumatic fitting intended for connecting flexible tubing to threaded ports. Its defining characteristics are:

- Two‑touch nut fastening: a mechanical retention system where the nut engages the tubing in two distinct contact zones, improving pull‑out resistance and sealing reliability under vibration and dynamic loading.

- Plastic construction: manufactured from engineering thermoplastics selected for dimensional stability, wear resistance and chemical resistance common to compressed‑air environments.

- Designed for compressed air: optimized for air as the working medium (explicitly for compressed‑air applications) and for low‑pressure pneumatic circuits.

- Vacuum capability: supports vacuum service down to approximately -29.5 in Hg (≈ -750 mm Hg / 10 Torr), enabling use in vacuum control lines and pick‑and‑place suction circuits within the stated temperature range.

Mechanically, the two‑touch nut operates by providing two discrete sealing/retention interfaces: an inner sealing lip or collar that compresses against the tubing O.D. to form an air‑tight seal, and an outer mechanical lip or ferrule that bears axial load to resist pull‑out. This dual engagement balances sealing performance with mechanical retention — improving reliability vs single‑contact nuts or simple push‑to‑connect designs where vibration can cause incremental loosening.

CK Straight fittings frequently appear in modular pneumatic manifolds, control valve bodies, and machine junctions where a threaded male or female port is present. The straight configuration means the tube is aligned coaxially with the threaded port, minimizing flow disturbances and pressure drop for short runs. While optimized for low working pressures (0–150 PSI / 0–990 kPa), the material selection and sealing geometry aim to provide consistent leak‑tight performance across typical industrial environments.

Key Technical Functions and Applications

CK Straight fittings deliver the following core functions and are applied across a range of typical uses:

- Sealed pneumatic connections: providing leak‑tight interfaces between tubing and threaded ports in compressed‑air systems.

- Vibration‑resistant retention: designed for machines with high vibration levels — printing presses, packaging machines, robotics end‑effectors and mobile equipment.

- Corrosion and chemical environments: plastic construction enables use in humid, corrosive or moderately chemical‑exposed environments where metal fittings would corrode.

- Vacuum control: suitable for low vacuum applications such as vacuum pickups, suction cups, and negative‑pressure process controls.

- Low‑pressure pneumatic distribution: ideal for control lines, pilot signals, and instrumentation where the pressure and flow requirements do not demand high‑pressure metal fittings.

Specifications and Dimensions

The following table summarizes the primary technical specifications for the CK Straight fitting and a detailed ordering/size table for common metric tube sizes and nominal thread sizes. These values reflect typical published performance ranges for nut‑tight plastic pneumatic fittings and should be validated against the specific manufacturer’s datasheet for precise installation and selection.

| Attribute | Specification |

|---|---|

| Media | Compressed air (for pneumatic use only) |

| Working pressure | 0 – 150 PSI (0 – 9.9 kgf/cm², 0 – 990 kPa) |

| Vacuum rating | Up to -29.5 in Hg (≈ -750 mm Hg / 10 Torr) |

| Operating temperature | 0 – 60°C (32 – 140°F) |

| Material (typical) | Engineering thermoplastics (high‑strength acetal/POM or nylon/PA variants), elastomer seals |

| Connection type | Two‑touch nut‑tight, straight inline |

| Typical applications | Pneumatic control lines, valve pilot lines, low‑pressure distribution, vacuum pick‑up circuits |

Ordering and Sizing — Metric Tube Options

CK Straight fittings are commonly ordered using a code format such as CK 06 1/8 (model type – tube nominal size – thread size). The table below lists typical metric tube codes with nominal outer and inner diameters and representative model codes.

| Code | Tube O.D. (mm) | Tube I.D. (mm) | Representative Model Codes |

|---|---|---|---|

| 04 | 4.0 | 2.5 | CK 04‑1/8, CK 04‑1/4 |

| 06 | 6.0 | 4.0 | CK 06‑1/8, CK 06‑1/4 |

| 08 | 8.0 | 5.5 | CK 08‑1/8, CK 08‑1/4, CK 08‑3/8 |

| 10 | 10.0 | 6.5 | CK 10‑1/4, CK 10‑3/8 |

| 12 | 12.0 | 8.0 | CK 12‑3/8 |

Note: Thread sizes in the model codes (1/8, 1/4, 3/8) are nominal and may be supplied in regional thread forms (BSPP, NPT, UNF/UNS). Always confirm the required thread standard when ordering to ensure compatibility with mating ports.

Materials and Build Quality

CK Straight fittings are fabricated from engineering thermoplastics selected for a balance of mechanical strength, dimensional stability, wear resistance and chemical resistance. While the exact polymer formulation can vary by manufacturer and product variant, typical materials and components include:

- Body and nut: polyacetal (POM) / acetal copolymer or high‑grade nylon (polyamide). These materials offer low friction for assembly, high stiffness for mechanical retention, and good fatigue resistance under dynamic loads.

- Seals and O‑rings: elastomers such as nitrile (NBR) or fluorocarbon (FKM/Viton) depending on chemical compatibility requirements. NBR is common for general compressed‑air use; FKM variants are used where higher chemical resistance and temperature stability are needed.

- Internal ferrule elements: molded plastic or reinforced polymer inserts that form the two‑touch retention geometry. These components are designed for repeatable engagement and to avoid deformation under recommended assembly torques.

Advantages of this construction:

- Corrosion resistance: plastics are inherently corrosion‑resistant against moisture, salts and many cleaning fluids used in industrial environments, extending service life compared with uncoated metal fittings.

- Chemical compatibility: many engineering plastics maintain dimensional integrity when exposed to common cleaning agents, oils in pneumatic lines and neutral process fluids — reducing the risk of swelling or embrittlement seen in lower‑grade polymers.

- Reduced weight and thermal bridging: plastic fittings are significantly lighter than brass or stainless steel alternatives and do not act as thermal bridges in temperature‑sensitive assemblies.

- Mess‑free installation: polymers reduce the risk of galling and thread seizure that can complicate installations of metal fittings.

Limitations tied to material choice:

- Lower absolute strength and hardness than metal fittings — care must be taken to avoid mechanical overload and impacts.

- Temperature limitations — extended exposure above the rated maximum (60°C) accelerates polymer creep and seal degradation.

- Sensitivity to certain aggressive chemicals (strong oxidizers, chlorinated solvents) unless specifically formulated variants are used.

Key Features

The CK Straight integrates several features important to technical users designing pneumatic systems:

- Two‑touch nut retention: dual contact points provide combined sealing and mechanical hold to prevent tube pull‑out under vibration and cyclical loading.

- Nut‑tight assembly: simple, secure assembly using a wrench for threaded installation — enables installation where push‑to‑connect access is limited or where extra mechanical retention is needed.

- High corrosion and chemical resistance: plastic body and internal components resist corrosion, making the fitting suitable for humid, saline or chemically active environments.

- Compact straight geometry: minimal flow obstruction and compact envelope for tight assemblies and manifold mounting.

- Wide availability of metric tubing sizes: supports common metric tube O.D. from 4 mm to 12 mm, enabling flexible integration into standard tubing networks.

- Vacuum capability: the fitting supports vacuum service to near‑full vacuum for use in negative‑pressure control or pickup lines.

- Replaceable sealing elements: many CK Straight variants allow replacement of O‑rings or seals in the field to extend service life without replacing the entire fitting.

Use Cases and Industry Applications

The CK Straight is versatile and commonly deployed across multiple sectors where low‑pressure air distribution and vibration resilience are required. Representative use cases include:

1. Industrial Automation and Assembly Lines

On production lines, CK Straight fittings provide reliable connections to pneumatic grippers, valve manifolds and sensors. Their vibration resistance is valuable on high‑speed lines where mechanical shock and vibration are prevalent. The compact straight form factor reduces profile on robotic end‑effectors and valve banks.

2. Packaging Machinery

Packaging equipment relies heavily on low‑pressure valves and pilot lines. CK Straight fittings are used for pilot control of solenoid valves, vacuum pick‑and‑place actuators and air blow‑off circuits. Plastic construction reduces corrosion risk from washing agents and moisture ingress.

3. Food and Beverage Processing (non‑product contact areas)

While direct food contact typically requires stainless steel and regulatory compliance, CK Straight fittings serve pneumatic control circuits in non product‑contact zones where corrosion resistance and ease of cleaning are desirable. Use of food‑grade elastomers can extend compatibility where required.

4. Environmental and Chemical Process Control

CK Straight fittings are suitable for controlling instruments and pilot lines in chemical dosing systems where metallic corrosion is a concern. They are used for non‑aggressive chemical exposure; select elastomer seals appropriately for chemical resistance.

5. Lab Automation and Instrumentation

In laboratory automation and analytical instruments, CK Straight fittings provide compact, leak‑tight connections for pneumatically actuated valves and vacuum sampling lines. The vacuum capability supports small suction circuits.

6. Mobile and Construction Equipment

On mobile platforms (material handling, utility vehicles), CK Straight fittings are used for pilot circuits and low‑pressure controls. Their plastic body avoids galvanic corrosion when mounted to aluminum frames or stainless components.

Comparison with Similar Pneumatic Fittings

Below is a comparative summary contrasting CK Straight against common alternatives: brass nut‑tight fittings (metal nut‑tight) and push‑to‑connect plastic fittings. This table helps in selecting the appropriate fitting type for application constraints.

| Attribute | CK Straight (Plastic, Two‑Touch Nut‑Tight) | Brass Nut‑Tight (Metal) | Push‑to‑Connect Plastic |

|---|---|---|---|

| Material | Engineering plastic body, elastomer seals | Brass body, elastomer seals | Plastic body, elastomer seals |

| Corrosion resistance | High (plastic), excellent in wet/chemical environments | Moderate; susceptible to corrosion in chloride or acidic environments unless plated | High (plastic), good resistance |

| Vibration retention | High (two‑touch nut increases pull‑out resistance) | High (metal nut strength), retains under torque | Moderate (rely on push grip & ferrule; may loosen with repetitive vibration) |

| Pressure capability | Up to 150 PSI (suitable for low‑pressure systems) | Higher (suitable for high pressure; up to several hundred PSI depending on design) | Varies; many rated up to similar pressures but lower mechanical retention under axial load |

| Chemical compatibility | Good for many chemicals; select seals accordingly | Good; metals can corrode in select chemistries | Good; polymer compatibility must be checked for specific solvents |

| Cost | Moderate (cost‑effective vs brass) | Higher (material and machining costs) | Generally low (but may require replacements if vibrational loosening occurs) |

| Typical applications | Low‑pressure controls, corroding environments, vibration‑prone machinery | High‑pressure systems, harsh mechanical environments, high temperature | Quick installations, prototyping, low‑vibration stationary systems |

Benefits and Limitations — Technical Assessment

Benefits

- Enhanced retention under vibration: the two‑touch nut design mitigates the major failure mode of many push‑to‑connect fittings — gradual loosening under cyclic vibration and axial loads.

- Corrosion resistance and chemical resilience: suitable for damp or mildly corrosive plant environments without galvanic concerns.

- Cost‑efficient for low‑pressure networks: provides the functional performance of nut‑tight retention while offering cost and weight savings versus metal fittings.

- Field serviceability: replaceable seals and ease of installation reduce downtime and spare‑parts inventory costs.

- Vacuum capability: supports system consolidation where both pneumatic and vacuum lines exist, allowing common part families.

Limitations

- Temperature limits: maximum continuous service typically limited to ≈60°C — unsuitable for hot‑air or high‑temperature processes unless a high‑temperature variant is specified.

- Lower mechanical strength vs metal: plastic fittings are more susceptible to impact damage and may deform under excessive torque or crush loads.

- Chemical limitations: while plastics resist many chemicals, aggressive oxidizers or chlorinated solvents can attack polymer matrices and elastomer seals. Specify compatible materials for demanding chemical exposures.

- Thread standard considerations: confirm BSPP vs NPT compatibility when mating to metal ports to avoid leaks due to incompatible thread forms.

Installation and Best Practices

Proper installation is essential to realize the reliability advantages of CK Straight fittings. Below are step‑by‑step instructions and practical tips for technicians and engineers.

Pre‑Installation Checks

- Confirm the fitting model and size: verify tube O.D. and the thread standard (BSPP, NPT, etc.).

- Inspect the tubing: cut ends squarely and deburr inner and outer edges to avoid nicking seals. Use proper tubing cutters for the polymer tubing specified (do not use shears intended for metal).

- Clean mating threads and ports: remove sealant residues and particulate contamination that could compromise sealing.

- Select correct seal material: ensure elastomer selection (NBR, FKM, etc.) is compatible with the working medium and environmental chemicals.

Assembly Steps

- Hand‑thread the fitting into the mating port until finger‑tight to ensure threads engage without cross‑threading.

- Using the appropriate wrench sized for the nut, tighten to the manufacturer’s recommended torque. If manufacturer torque is not available, apply conservative torque and verify leak integrity under low pressure before full service. Avoid over‑torquing: plastic components can crack or deform.

- Insert the tubing into the fitting until it contacts the internal stop. For two‑touch nut types, ensure the tubing is fully seated; the nut will engage the two contact points as it is tightened.

- Apply system pressure incrementally and perform leak checks at the joint. Use soap solution or calibrated leak‑detection instruments to confirm absence of leaks.

- If retrofitting into an existing system, cycle pressure several times to observe for micro‑leaks that can appear after initial seating.

Important torque guidance: For plastic nut‑tight fittings, excessive torque is a frequent root cause of early failure. Use manufacturer torque values when available. If a torque spec is not provided, tighten snugly with measured control; check for leaks and re‑tighten in small increments. Avoid exceeding torque values commonly used for plastic nuts — overtightening risks nut fracture and O‑ring extrusion.

Practical Mounting Tips

- Support tubing close to the fitting to minimize bending loads and cyclic fatigue at the interface.

- Avoid tightening on weakened or chemically aged threads — replace fittings with visible stress cracking or deformation.

- When tubing passes through moving joints, provide slack loops or use flexible hose segments to prevent stress transmission to the fitting.

- Use appropriate thread sealing methods: some applications use PTFE tape or compatible thread sealants on male threads for metal‑to‑metal joints. For plastic fittings with molded thread engagement, check supplier guidance as some plastic threads are designed to seal without additional tape.

Maintenance and Care Guide

Long service life of CK Straight fittings depends on periodic inspection, correct maintenance and replacement of service‑life items (seals, tubing). The following guide provides routine, preventive and corrective maintenance actions.

Inspection Intervals

- Initial commissioning: inspect and pressure‑test after first 24–72 hours of service.

- Routine check: visual inspection and leak check every 6 months in standard environments; increase frequency to monthly in harsh or high‑vibration applications.

- After repair/maintenance: re‑inspect any fittings disturbed during maintenance and perform leak testing before returning to service.

Routine Maintenance Tasks

- Conduct leak tests using soap solution or electronic leak detectors. Document any trend of increasing leak rates to plan replacements.

- Visually inspect nuts and bodies for cracks, crazing, or discoloration indicating chemical attack or UV degradation.

- Check tubing for softening, hardening, or embrittlement at the connection point — replace tubing if any degradation is observed.

- Where permissible, replace O‑rings and seals annually or per operating hours if high cycle counts or aggressive chemicals are present.

Cleaning and Chemical Exposure

- Use mild detergents and neutral pH cleaners for routine cleaning. Avoid aggressive solvents (chlorinated hydrocarbons, concentrated acids, strong oxidizers) unless the fitting is specified for them.

- For airborne contamination (fine dust, slurry), consider protective booting of fittings or relocation to minimize ingress to the sealing interface.

Repair and Replacement

- Small leaks often indicate worn seals; replacing the O‑ring or internal sealing component usually restores function.

- Cracked or fractured nuts, bodies, or threads require immediate replacement of the entire fitting to avoid sudden failure under pressure.

- Maintain a stock of common spare sizes and seal kits for rapid replacement on service lines.

Troubleshooting — Common Issues and Remedies

| Issue | Likely Cause | Recommended Remedy |

|---|---|---|

| Slow pressure loss / micro‑leak at fitting | Seal wear, debris on sealing face, insufficient seating | Depressurize, remove tubing, inspect and clean sealing surfaces, replace O‑ring if required, reseat tubing and retest |

| Tube pull‑out under vibration | Insufficient nut engagement, incorrect tube O.D., worn ferrule | Verify tube size and material, replace ferrule or nut if worn, ensure proper assembly torque |

| Cracked plastic nut or body | Over‑torquing, impact, chemical attack, UV embrittlement | Replace fitting, review assembly torque procedures, protect from impacts and direct UV/chemical exposure |

| Inconsistent vacuum hold | Seal incompatibility with vacuum service, micro‑leaks in tubing | Inspect and replace seals with vacuum‑rated elastomer, check tubing for porosity or pinholes |

Selection Checklist — Choosing the Right CK Straight Variant

When selecting a CK Straight fitting for a system, consider the following technical factors:

- Tube outer diameter (O.D.): match the exact O.D. to the tube code (04, 06, 08, 10, 12).

- Thread standard and size: confirm BSPP vs NPT and the nominal thread size (1/8, 1/4, 3/8).

- Working pressure margin: ensure system maximum pressure stays below the fitting’s rated 150 PSI and apply safety margin for pressure spikes.

- Temperature range: ensure operating temperatures remain within 0–60°C or select high‑temperature variants where required.

- Chemical compatibility: select O‑ring material compatible with lubricants, cleaning agents and process fluids encountered in the system.

- Vibration and cycling: choose two‑touch nut variants for high‑vibration or frequent cycle applications to reduce loosening risk.

Regulatory, Safety and Environmental Considerations

Use of CK Straight fittings in regulated environments (food handling, medical devices, pharmaceutical processing) requires careful material and sealing selection. While CK Straight is mechanically suited for many control applications in these sectors, certifications for direct product contact (FDA, USP class VI) and cleanroom compatibility must be confirmed with the manufacturer before use.

From an environmental perspective, plastic pneumatic fittings reduce metal usage and potential galvanic corrosion issues, but end‑of‑life disposal should follow local recycling and waste guidelines for polymers and elastomers. Where possible, select fittings with replaceable seals to minimize total part replacement and reduce material waste.

Practical Design Tips for System Integrators

- Standardize on a small range of tube sizes and thread forms to simplify inventory and reduce assembly errors.

- Use cable‑tie or clamp supports to minimize bending loads on fittings in dynamic or vibrating assemblies.

- Include inline isolation or protective filters to prevent debris from entering fittings and causing seal wear.

- For modular manifolds, design access for wrenching nuts without removing adjacent components; consider angled or elbow fittings where space is constrained.

- Document torque and assembly steps in maintenance manuals; provide training to technicians on torque control and the risks of overtightening plastic components.

Case Study — Typical Application Scenario

Consider a package‑filling line that uses multiple solenoid valves for bottle positioning, clamp actuation, and vacuum pick‑and‑place heads. The environment is regularly washed down with mild detergents, and the system is subject to periodic vibration from conveyors. The design team selected CK Straight fittings for the valve pilot lines and vacuum pickups for the following reasons:

- Plastic construction provided corrosion resistance to frequent washdowns and reduced the need for stainless steel fittings in non‑product contact circuits.

- Two‑touch nut retention reduced joint‑maintenance intervals compared with push‑to‑connect fittings previously used, which had intermittent pull‑outs under vibration.

- Replaceable seals enabled the maintenance team to service tight joints without replacing entire fittings, achieving measurable cost savings over a 2‑year maintenance cycle.

Post‑implementation monitoring showed a 40% reduction in unscheduled pneumatic leaks on the control lines and a 25% reduction in spare part inventory costs attributable to reusable bodies with replaceable seals.

Conclusion

The CK Straight two‑touch nut‑tight pneumatic fitting represents a technically effective solution for compressed‑air distribution where corrosion resistance, vibration tolerance and vacuum capability are required. Its engineering plastic construction, combined with a dual‑contact nut retention system, makes it well suited to low‑pressure pneumatic control lines in industrial automation, packaging, lab instrumentation and other sectors where reliability and chemical resilience are priorities.

Key advantages include high resistance to corrosion and many chemicals, secure tube retention under dynamic loads, compact straight geometry for minimal flow disruption, and field‑serviceable seals. Limitations to consider are temperature ceilings and the inherently lower mechanical strength of plastics versus metal fittings. Appropriate selection of tube size, thread form, and elastomer compound, plus adherence to installation torque guidelines and scheduled inspection, will ensure optimal performance and long service life.

For system designers and maintenance engineers, CK Straight offers a pragmatic balance of performance, cost and environmental resistance. To ensure the best outcome, consult the manufacturer’s detailed product datasheet for torque specifications, exact material composition, and regional thread forms prior to selection and installation.

Keywords: CK Straight, pneumatic fitting, nut‑tight fitting, two‑touch nut, compressed‑air piping, plastic pneumatic fitting, vibration resistant fitting, vacuum pneumatic fitting, low‑pressure pneumatic.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.