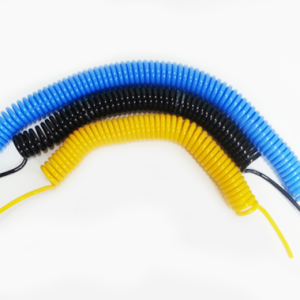

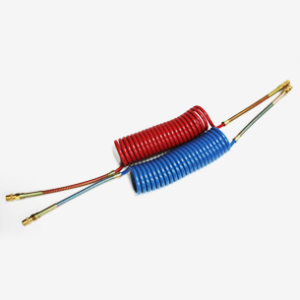

Air Coil Hose (PE) — Technical Guide and Product Overview

The Air Coil Hose (PE) is a coiled pneumatic hose engineered for low‑pressure compressed‑air applications. Constructed from EVA (ethylene vinyl acetate) / PE blend, this hose combines lightweight construction, strong corrosion resistance and high elasticity in a compact, coilable form. Supplied with a one‑touch coupler for rapid connections, the hose is designed to resist tangling, recover quickly after extension and deliver reliable airflow for general workshop and industrial air supply tasks operating at low pressures (up to 5 kgf/cm² or equivalent).

Introduction

Coiled air hoses have become a standard component in many workshops, assembly lines and maintenance areas because they significantly reduce floor clutter, tangling and storage footprint while providing instant reach to air tools. The Air Coil Hose (PE) is targeted at users who require a lightweight, corrosion‑resistant, and quickly deployable pneumatic hose for low pressure duty: air blowguns, precision air tools, intermittent tool use at workstations, and general plant maintenance.

This document provides a comprehensive technical overview, specifications, technical advantages and limitations, installation and maintenance guidance, and comparisons with other coil hose materials. It is written for technical readers and procurement specialists evaluating hose solutions for light industrial pneumatic systems.

Technical Overview

The Air Coil Hose (PE) is a helically pre‑formed tube manufactured from an EVA‑based polyethylene (PE) compound. Because of the coil form, a short free length is maintained when the hose is not in use; when pulled it extends to a longer working length and then returns to the coiled state after release. This geometry minimizes tangling and reduces the need for additional hose reels or cable management.

Primary functions

- Deliver compressed air to handheld tools, blowguns, pneumatic actuators and temporary fixtures.

- Provide a compact, recoilable connection that stores itself when not in use.

- Allow rapid connection/disconnection using the supplied one‑touch coupler for efficient tool changes.

Typical applications

- Workshop air supplies for blowguns and hand tools.

- Production line tool drops and assembly stations.

- Automotive maintenance bays and tire shops (low pressure tasks such as blowing debris, inflating low pressure fittings).

- Portable test benches and temporary pneumatic setups where compact storage is desirable.

The material selection (EVA/PE) yields a hose that is lighter and stiffer than some polyurethane alternatives, which benefits coil stability and return recovery. It resists many common contaminants encountered in workshops, such as water, mild oils and cleaning agents, while its elasticity reduces the risk of permanent deformation after repeated extension cycles.

Specifications and Dimensions

Below is a representative specification table giving the common configurations of the Air Coil Hose (PE). Models vary by internal diameter, nominal uncoiled (extended) length, and hardware supplied. These values are realistic and intended for selection guidance; verify exact values with the manufacturer for ordering.

| Model | Inner Diameter (ID) | Outer Diameter (OD) | Coiled Length | Maximum Extended Length | Wall Thickness | Working Pressure (max) | Burst Pressure (typical) | Weight (approx.) | Coupler |

|---|---|---|---|---|---|---|---|---|---|

| AC‑PE‑4×5 | 4.0 mm | 7.5 mm | 0.9 m | 5.0 m | 1.75 mm | 5 kgf/cm² (≈4.9 bar / 71 psi) | 15 kgf/cm² (≈14.7 bar / 215 psi) | ~45 g (total) | 1/4″ One‑touch (male) |

| AC‑PE‑6×8 | 6.0 mm | 10.5 mm | 1.0 m | 8.0 m | 2.25 mm | 5 kgf/cm² (≈4.9 bar / 71 psi) | 15 kgf/cm² (≈14.7 bar / 215 psi) | ~85 g (total) | 1/4″ One‑touch (male) |

| AC‑PE‑8×10 | 8.0 mm | 12.5 mm | 1.2 m | 10.0 m | 2.25 mm | 5 kgf/cm² (≈4.9 bar / 71 psi) | 15 kgf/cm² (≈14.7 bar / 215 psi) | ~120 g (total) | 1/4″ One‑touch (male) |

Notes:

- Working pressure is specified per product information as a maximum of 5 kgf/cm² (which equates to approximately 4.9 bar / 71 psi). Do not exceed this operating pressure.

- Burst pressure shown is typical and assumes a standard safety factor of 3× working pressure. Actual burst pressure values depend on wall thickness, manufacturing tolerances and ambient temperature.

- Coupler is normally a 1/4″ quick‑connect one‑touch male to fit standard 1/4″ couplers on tools and reels. Other thread/coating options (e.g., NPT, BSP, nickel plating) may be available on request.

Materials and Build Quality

The key material in the Air Coil Hose (PE) is an EVA‑modified polyethylene compound (EVA/PE). This compound provides a balanced property set compared to pure PVC or pure polyurethane hoses:

Material composition and rationale

- EVA content: Adds elasticity and impact resistance, improving coil memory and recovery after extension.

- PE base: Provides chemical and corrosion resistance, excellent moisture resistance and a low density, reducing overall weight.

- Optional additives: UV stabilizers, anti‑ozonants and plasticizers (if used) are chosen to maintain mechanical properties across the specified temperature range and improve outdoor durability.

Construction details

- Extruded single‑layer tube formed into a helical coil using a mandrel forming process. Coil pitch and diameter are controlled to ensure reliable recovery and consistent internal flow path.

- Precision cut and fitted with a one‑touch quick coupler assembly at one or both ends. Coupler materials are typically nickel‑plated brass or stainless steel for corrosion resistance in workshop environments.

- End fittings are typically crimped or mechanically secured. High quality assemblies use stainless or plated crimp sleeves and may include an internal backup ring to prevent pull‑out under stress.

Durability and expected lifecycle

While EVA/PE materials are less abrasion resistant than some polyurethane compounds, the coiled geometry reduces exposed length and contact with abrasive surfaces, improving life in typical workshop use. Typical lifecycle expectations depend on usage patterns:

- Intermittent workshop use (blowgun, occasional tool): multiple years of service expected if used within rated pressure and temperature ranges.

- Continuous heavy duty industrial use with high tool throughput: shorter life than heavy duty rubber or PU lines; periodic replacement is likely within 1–3 years depending on environment.

Corrosion resistance is excellent due to the inherently inert nature of PE and the non‑metallic exposed body. Couplers and fittings remain the primary wear points; choose plated or stainless materials for aggressive or humid environments.

Key Features

The following list summarizes the most important features and their technical implications.

- Coil geometry (pre‑formed): Compact storage, minimal tangling, automatic recoil and easy tool reach management. Coil provides an initial free length and pulls out smoothly under load.

- EVA/PE compound: Lightweight, corrosion‑resistant and elastic; good chemical resistance to water and many cleaning agents; resists permanent set.

- One‑touch quick coupler: Rapid tool changes and secure, leak‑resistant connection. Compatible with standard 1/4″ coupler systems commonly used across workshops and industrial plants.

- Low mass: Reduced operator fatigue when hand‑held and reduced load on tool hangers and brackets.

- Resistance to tangling: Coil form and controlled stiffness prevent knots and cross‑wraps typical of straight hoses.

- Fast recovery: High elasticity and coil memory bring the hose back to coiled form in seconds, keeping workspaces tidy.

- Compact footprint: Eliminates the need for reels in many low‑use scenarios and simplifies workstation design.

- Economical: Lower material costs compared with heavy‑duty rubber hoses; simplified handling reduces downtime during tool changes.

Performance Characteristics

When selecting a coiled air hose, consider the following technical performance characteristics:

Flow capacity and pressure drop

Flow capacity is principally a function of internal diameter and extended length. Smaller IDs increase pressure drop, which can reduce tool performance for air motors and high‑flow tools. General guidance:

- 4 mm ID — Suitable for air blowguns, spray nozzles, and low‑flow tools where small volume and precision are required. Not recommended for high‑flow pneumatic wrenches or air motors.

- 6 mm ID — Good general purpose compromise for common hand tools, intermittent impact wrenches of small to medium size, and assembly tools.

- 8 mm ID — Better for higher airflow demands such as larger pneumatic tools, higher duty rates or longer extended lengths where pressure drop would otherwise be excessive.

For critical tool selection, consult pressure‑drop charts or run simple flow calculations. As a rule of thumb, keep extended hose length short and select the largest practical ID for power‑hungry tools.

Temperature range

Typical EVA/PE coil hoses operate reliably from approximately -10 °C to +60 °C (14 °F to 140 °F). Material stiffness increases at low temperatures, which may temporarily reduce coil recovery; at higher temperatures beyond the recommended range, elastomeric softening and reduced burst strength can occur. If your environment exceeds these conditions, consider alternative materials or heated storage.

Chemical compatibility

PE/EVA resists water, diluted cleaning agents, many detergents and atmospheric exposure. It has limited resistance to strong hydrocarbons, concentrated solvents, and aggressive acids/alkalis. Always verify compatibility when exposed to oils, fuel, brake fluid or solvent vapors — these can swell or embrittle the compound over time.

Use Cases / Applications

The Air Coil Hose (PE) is optimized for low‑pressure, intermittent pneumatic tasks where compact storage, rapid handling and corrosion resistance are desirable. Common use cases include:

Workshop and Garage

- Blowguns, general cleaning and light pneumatic tool use where hoses are frequently picked up and put down.

- Mechanic bays where floor space is limited and quick access to a short reach hose is required.

- Inflation tools for tires on passenger vehicles (observe pressure limits and recommend dedicated inflation lines for high‑pressure pneumatic use).

Assembly Line Stations

- Workstation tool drops where multiple operators share a single hose point and the coil prevents tangles and overhead obstruction.

- Small screwdrivers, riveters and air brushes used intermittently with quick tool swaps.

Maintenance and Service Areas

- Portable test benches and temporary compressed air connections during servicing tasks.

- Maintenance carts and tool trolleys where hose weight and storage volume must be minimized.

Lab and Light Industrial Use

- Low‑pressure pneumatic instrumentation and laboratory air lines where cleanliness and non‑reactivity are desirable.

- Areas requiring corrosion resistance (e.g., damp or mildly corrosive environments) where metal tubing would corrode.

Comparison with Similar Products

To assist procurement and engineering decisions, the following table compares the Air Coil Hose (PE) to coil hoses made from common alternative materials: polyurethane (PU) and PVC, and a standard rubber (EPDM) coil hose option where applicable.

| Attribute | Air Coil Hose (PE / EVA) | Polyurethane (PU) Coil Hose | PVC Coil Hose | Rubber (EPDM) Coil Hose |

|---|---|---|---|---|

| Weight | Very light | Light | Light to moderate | Moderate to heavy |

| Elasticity / Coil memory | Good (fast recovery) | Excellent (best memory) | Good | Poor to moderate |

| Abrasion resistance | Moderate | High | Moderate | High |

| Chemical resistance | Good to water/cleaners; limited to hydrocarbons | Good; broad chemical resistance | Variable; not resistant to strong solvents | Good to oils and heat |

| Low-temperature flexibility | Moderate (-10 °C typical) | Excellent (-30 °C range possible) | Poor to moderate | Good |

| Cost | Low–medium | Medium–high | Low | High |

| Best for | Light workshop use, corrosion resistance, compact storage | High wear, frequent flexing, harsh environments | Economy applications, indoor low‑duty | Heavy duty, higher temp and abrasion environments |

Interpretation:

- PU hoses generally provide the best trade‑off for abrasion resistance and elasticity, but at higher cost.

- PVC hoses are cost effective but less flexible at low temperatures and less chemically robust.

- Rubber (EPDM) coil hoses are heavier but resist abrasion and heat well; they are typically used when durability outweighs compactness.

- The Air Coil Hose (PE) sits in the economical, corrosion‑resistant, lightweight segment that is ideal for many station‑level pneumatic needs.

Benefits and Limitations

Benefits

- Compact and tidy storage: Coil geometry shortens free length and reduces workplace trip hazards and tangles.

- Lightweight and low operator fatigue: Easier to handle for handheld tools and carts.

- Good corrosion and moisture resistance: PE base resists water ingress and corrosion‑related degradation better than metallic or some elastomeric hoses.

- Quick connect/disconnect: One‑touch coupler improves ergonomics and throughput on production lines.

- Fast recovery: Elastic memory returns hose to coil, improving housekeeping and preventing droop.

Limitations

- Limited maximum pressure: Rated for low pressure duty (≤5 kgf/cm²). Not suitable for high‑pressure pneumatic systems or demanding pneumatic hydraulics.

- Abrasion resistance: EVA/PE is less abrasion‑resistant than TPU and rubber; avoid dragging across sharp edges or abrasive floors.

- Chemical exposure: Not recommended for prolonged exposure to fuels, concentrated solvents or aggressive chemicals without confirming compatibility.

- Temperature sensitivity: Performance diminishes at temperatures below the specified range; coil recovery slows in cold conditions.

- Flow limitation at small IDs: For high flow tools or long extended lengths, ID sizing must be carefully selected to avoid unacceptable pressure drop.

Selection and Installation Guide

Selecting the right Air Coil Hose (PE) model requires matching hose geometry, ID and fittings to the application. Below is a step‑by‑step guide to ensure good performance and safety.

1. Determine required flow and pressure

- List all pneumatic tools and their required supply pressure and flow (l/min or scfm).

- Calculate worst‑case flow through the hose when multiple tools share the same line.

- Select an ID that limits pressure drop to acceptable levels at the typical extended length; choose 8 mm for high flow, 6 mm for general purpose, 4 mm for light tasks.

2. Verify working and burst pressures

- Confirm the system supply pressure does not exceed the hose working pressure (max 5 kgf/cm² for this product).

- Allow suitable safety margin for pressure spikes and downstream blockages.

3. Pick the correct length and coil size

- Consider the maximum practical extension you need at a work station. Smaller coils reduce extension but keep footprint compact.

- Longer maximum extended lengths increase total unfolded volume and pressure drop; size accordingly.

4. Choose compatible couplers and fittings

- Verify that the one‑touch coupler thread and profile matches the tools and plant fittings (typical 1/4″ BSP or NPT quick‑coupler standard).

- Consider stainless or plated couplers for humid or corrosive environments.

5. Mounting and routing

- Provide a fixed anchor point at the supply side if practical to keep the coil returning to a controlled location.

- Avoid sharp bends and kinks; ensure the coiled hose has clearance to recover its form without rubbing on edges.

- Do not route across high temperature surfaces or near hot exhausts.

6. Safety considerations

- Never exceed the rated working pressure. Use pressure regulators and pressure relief devices where necessary.

- Do not use for breathing air or oxygen unless explicitly certified for such service.

- Inspect fittings and couplers for wear; replace if leaking or if locking mechanisms do not operate reliably.

Maintenance and Care Guide

Proper maintenance extends life and maintains performance. The Air Coil Hose (PE) requires minimal care, but the following professional tips will help ensure long life and reliable operation.

Routine visual inspections

- Inspect the hose and coupler before each shift or at regular intervals for cuts, nicks, abrasions or chemical attack.

- Look for discoloration or stiffness that may indicate UV or chemical degradation.

Connections and couplers

- Ensure coupler mating surfaces are free of debris and dirt to avoid leaks and wear.

- Lubricate quick coupler internal seals occasionally with a manufacturer‑approved lubricant to prevent seal drying and sticking.

- Check crimp sleeves and ferrules for deformation and replace fittings that show permanent damage.

Cleaning

- Wipe down with mild detergent and water; rinse thoroughly and allow to dry before re‑pressurising.

- Avoid strong solvents or degreasers which may attack the EVA/PE compound.

Storage

- Store coiled hoses in a cool, shaded area away from direct sunlight and heat sources to slow UV and thermal degradation.

- Avoid long term exposure to oil pools, solvents or fuel where chemical attack could occur.

Testing and replacement

- Perform pressure leak testing when installing or after maintenance; verify no leaks at couplings or along the body.

- Replace hoses that show permanent elongation (loss of coil memory), surface cracking or visible swelling.

- Keep a record of hose service life and replacement intervals for audit and reliability planning.

Installation Examples and Best Practices

Below are practical installation examples and best practices to maximize effectiveness of the Air Coil Hose (PE).

Workstation Tool Drop

- Mount a fixed feed point with a 1/4″ male quick coupler at bench edge, approximately 0.3–0.5 m above the bench surface.

- Attach the coiled hose (coiled length facing down). Use a small cable clamp to anchor the hose end to the bench for controlled recoil.

- Route the coil so it can extend towards the work area without contact with nearby equipment or conveyors.

Mobile Maintenance Cart

- Secure a compact coiled hose reel or quick‑release coupling on the cart frame.

- Attach the hose to the cart regulator; use a 6 mm ID model if multiple tools will be used from the cart to reduce pressure drop.

- Store the coiled hose in a protected pocket or loop to avoid ground abrasion when the cart is moved.

Safety Interlocks and Pressure Regulation

- Install a pressure regulator and pressure gauge at the source to prevent over‑pressurization of station hoses.

- Consider an inline check valve or flow limiter if multiple operators will intermittently tap the same feed to prevent system surges.

Testing, Certification and Compliance

The Air Coil Hose (PE) should be tested and verified for safe operation according to internal quality procedures and applicable local regulations. While specific certification requirements vary by industry and region, consider the following general tests and verifications:

- Hydrostatic pressure test: Pressure test to the specified burst margin (e.g., 1.5–3× working pressure) to ensure no manufacturing defects.

- Leakage/air tightness test: Verify coupler seals, end terminations and hose body for leakage under maximum working pressure.

- Dimensional inspection: Confirm ID/OD, wall thickness, and coil pitch conform to specification tolerances.

- Material analysis: Traceability of polymer compounds and any additives for compliance with in‑house or regulatory material lists.

If the hose will be used in regulated sectors (e.g., food processing, breathing air, medical), seek hoses with appropriate certifications for those applications — many EVA/PE hoses are not certified for breathing air or food contact unless specifically manufactured and certified for such service.

Troubleshooting Common Issues

Below are common issues encountered with coiled hoses and recommended corrective actions.

Issue: Hose does not fully recoil

- Possible causes: plastic memory degradation, cold temperature stiffening, or internal deformation from over‑extension.

- Corrective action: Move hose to warmer environment, inspect for permanent elongation or kinks, replace if memory loss is permanent.

Issue: Excessive pressure drop at tool

- Possible causes: undersized ID, long extended length, partial blockage or coupler restriction.

- Corrective action: Use larger ID, shorten extended length, inspect and clean couplers and inline filters, or move to a dedicated short feed line for high‑flow tools.

Issue: Leakage at coupler

- Possible causes: worn O‑ring, damaged coupler body, or loose termination.

- Corrective action: Replace O‑rings and coupler parts, re‑crimp or re‑terminate hose end, use proper coupler grease for seal longevity.

Procurement Checklist

Use this checklist when specifying or ordering Air Coil Hoses for an installation:

- Confirm maximum working pressure and burst margin required by system.

- Decide required inner diameter and maximum extended length for the most demanding tool.

- Specify coupler thread / standard (e.g., 1/4″ BSP or NPT) and desired plating or stainless material.

- Determine operating temperature extremes and chemical exposures.

- Ask manufacturer for test certificates, pressure test data and material composition if required for quality assurance.

- Plan for spare hoses and replacement intervals if the use case is heavy duty.

Environmental and Safety Considerations

When using the Air Coil Hose (PE), observe standard safety and environmental practices:

- Dispose of damaged hoses in accordance with local polymer waste regulations; many PE/EVA compounds are not readily recyclable in standard streams.

- Do not use the hose for hazardous gases (e.g., oxygen, acetylene) unless explicitly specified and certified for such use.

- Use PPE where compressed air could create debris or cause eye hazards; do not blow compressed air at personnel.

- Secure hoses to prevent whipping if a coupler separates under pressure; maintain a secure mounting and use safety clips where necessary.

Case Study: Implementing Air Coil Hose (PE) in an Assembly Cell

A mid–sized electronics assembly plant replaced a bank of straight PVC hoses with Air Coil Hose (PE) drops at each workstation to reduce clutter and speed up tool changeover. Key outcomes included:

- Reduced floor obstructions and tangling, improving operator ergonomics and lowering trip‑hazard incidents.

- Tool changeover times decreased by 25% due to the one‑touch coupler and compact hose positioning.

- Maintenance calls for hose tangles and kinking fell to nearly zero, although periodic coupler replacement was required after 18 months at high cycles.

Lessons learned: Ensure tool airflow requirements were verified prior to changing hoses — one station required an upgrade to 8 mm ID to avoid pressure drop during peak tool use.

Summary and Conclusion

The Air Coil Hose (PE) is a practical, economical, and ergonomically efficient solution for many low‑pressure pneumatic applications. Engineered from an EVA/PE compound, it offers lightweight construction, good corrosion resistance, and reliable coil memory for compact storage and minimal tangling. The inclusion of a one‑touch coupler improves handling and throughput in workshop and assembly environments.

It is best suited to applications that demand a tidy work area, infrequent or intermittent tool use, and where operating pressures do not exceed 5 kgf/cm². For higher abrasion, high‑pressure or extreme temperature environments, consider alternative materials such as polyurethane or rubber. Proper selection of inner diameter and extended length will ensure sufficient flow and tool performance, while routine inspection and correct handling will maximize service life.

In sum, for light industrial and workshop pneumatic duties, the Air Coil Hose (PE) delivers a strong balance of convenience, corrosion resistance and cost efficiency — making it an excellent choice for workstation drops, maintenance carts and assembly line tool management where compactness and ease of use are key.

Further Information and Support

For technical datasheets, material safety data sheets, or certifications related to specific part numbers and coupler options, contact your supplier or manufacturer. Always request batch test data for critical installations and consult pneumatic engineers for system design where multiple tools share common lines or require coordinated pressure management.

If you have a specific application in mind (tool type, flow requirements, expected duty cycle), provide those details and a recommended configuration (ID, length, coupler) can be proposed to match your needs.

Keywords: Air Coil Hose, EVA PE hose, coiled pneumatic hose, one‑touch coupler, low pressure air hose, workshop air supply, coil recovery, tangling‑resistant hose.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.