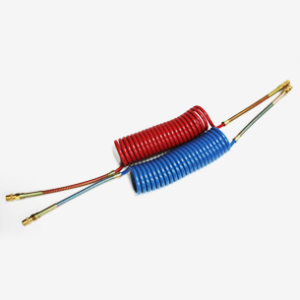

Individual Coil Hose — Lightweight, Low-Temperature Flexible Coiled Hose for Industrial Pneumatics and Fluid Handling

The Individual Coil Hose is a compact, resilient coiled hose engineered to deliver superior low-temperature flexibility, excellent abrasion and chemical resistance, and economical performance for a wide range of industrial and laboratory applications. More pliable than standard nylon tubing and offered in multiple colors for process identification and safety, this hose is purpose-built for applications where space, routing complexity, and environmental exposure demand a flexible, durable fluid conveying solution.

Introduction

Coiled hoses are an essential component in modern fluid power and pneumatic systems where flexibility, compact storage, and rapid extension and retraction are required. The Individual Coil Hose targets applications that require a balance of mechanical resilience and environmental tolerance while also remaining cost-effective. Typical use cases include automated assembly lines, robotic end-of-arm tooling, mobile diagnostic equipment, laboratory instrumentation, and general compressed air distribution in confined spaces.

This article provides a comprehensive technical examination of the Individual Coil Hose, including a detailed technical overview, specifications and dimensions, materials and build quality, key features, recommended use cases, comparative analysis with competing tubing types, maintenance and installation guidance, testing and QA practices, and regulatory considerations. The content is written for engineers, purchasing specialists, maintenance technicians, and system integrators evaluating flexible hose solutions for industrial and process environments.

Technical Overview

The Individual Coil Hose is a coiled, thermoplastic-based flexible hose that combines a smooth internal bore with an externally coiled geometry. The coiled form factor allows the hose to remain compact when not under load and to extend when needed, minimizing interference in dense assemblies and lowering the risk of snagging or kinking. Key performance attributes include:

- Low-temperature flexibility: Retains pliancy at sub-zero temperatures to support reliable operation in refrigerated environments and cold-weather outdoor installations.

- Abrasion resistance: Optimized surface hardness and additive packages for resistance to mechanical wear from contact with surfaces and repeated flex cycles.

- Chemical resistance: Formulations engineered to resist oils, diluted solvents, hydraulic fluids, and many cleaning agents commonly encountered in industrial settings.

- Lightweight and compact: Low mass per unit length and compact coiling reduce momentum and stress on fittings during motion.

- Multiple colors: Color-coding supports process control, safety segregation, and rapid visual identification of media or pressure classes.

Functionally, the Individual Coil Hose can be used for pneumatic control lines, instrument air, low-pressure fluid transfer, and vacuum applications (when specified), and is typically coupled with push-to-connect fittings, barbed adapters, or quick-connect couplers depending on system architecture.

Specifications and Dimensions

The following specification table provides representative, realistic values for typical variants of the Individual Coil Hose family. Exact values may vary by specific part number, material compound, and manufacturing tolerances. Typical production options include nominal internal diameters (I.D.) of 4 mm, 6 mm, 8 mm, and 10 mm (also offered in their nearest imperial equivalents). Dimensions below are provided in metric with imperial approximations for clarity.

| Nominal I.D. (mm / in) | Nominal O.D. (mm / in) | Wall Thickness (mm) | Coil Relaxed Length (mm) | Max Extended Length (mm) | Coil Outer Diameter (mm) | Working Pressure (bar / psi) | Burst Pressure (bar / psi) | Min Bend Radius (mm) | Weight (g/m) | Operating Temp Range (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| 4 mm / 5/32″ | 7.0 mm / 9/32″ | 1.5 mm | 80 mm | 400 mm | 25 mm | 8 bar / 116 psi | 32 bar / 464 psi | 10 mm | 25 g/m | -40 to +80 °C |

| 6 mm / 1/4″ | 9.5 mm / 3/8″ | 1.75 mm | 90 mm | 600 mm | 30 mm | 8 bar / 116 psi | 32 bar / 464 psi | 12 mm | 35 g/m | -40 to +80 °C |

| 8 mm / 5/16″ | 11.7 mm / 15/32″ | 1.85 mm | 100 mm | 900 mm | 35 mm | 8 bar / 116 psi | 32 bar / 464 psi | 15 mm | 45 g/m | -40 to +80 °C |

| 10 mm / 3/8″ | 14.0 mm / 9/16″ | 2.0 mm | 120 mm | 1200 mm | 45 mm | 8 bar / 116 psi | 32 bar / 464 psi | 20 mm | 60 g/m | -40 to +80 °C |

Notes on the table: Working pressure values above are typical for pneumatic service and are quoted at 20 °C. Burst pressure reflects a conservative 4:1 safety factor used by many manufacturers for small-bore thermoplastic hoses; customers should consult the specific product datasheet and system safety requirements when designing circuits.

Additional Measured Attributes

| Attribute | Typical Range / Value |

|---|---|

| Shore Hardness (A) | 82–92 Shore A (compound dependent) |

| Tensile Strength | 20–45 MPa |

| Elongation at Break | 300–700% |

| Abrasion Resistance (mm3 volume loss, ASTM D5963 style test) | 10–30 mm3 (lower is better) |

| Flex Life (cycles to failure at rated bend radius) | >100,000 cycles (typical in repetitive flex tests) |

Materials and Build Quality

The Individual Coil Hose is typically manufactured from engineered thermoplastic elastomers (TPE) or thermoplastic polyurethane (TPU) compound families. These materials are selected for their balanced mechanical properties—elasticity, abrasion resistance, and resistance to common industrial chemicals—and for their processability in continuous extrusion and coiling operations. The following sections describe the typical material structure and manufacturing practices that contribute to the hose’s performance.

Material Composition

- Core polymer: TPU/TPE base providing elasticity and a smooth internal bore. TPU is commonly used for its superior abrasion resistance and mechanical strength relative to many other thermoplastics.

- Additives: UV stabilizers, antioxidants, antistatic agents (optional), and colorants for color-coding. Flame-retardant additives can be incorporated for specific safety requirements (subject to trade-offs against flexibility).

- Optional reinforcement: For higher pressure variants, thin textile or micro-fiber reinforcement layers can be co-extruded to increase burst strength without degrading flexibility significantly.

- Surface treatment: A smooth, low-friction internal surface (to reduce pressure drop and particulate buildup) and a textured external coil geometry for flexibility and abrasion resistance.

Manufacturing Process

Manufacturing typically involves continuous extrusion of the chosen thermoplastic compound through a die sized for the target internal/external dimensions. Immediately following extrusion, the hose is formed into the coiled geometry using heated mandrels or coiling stations, which set the pitch and coil diameter. Post-extrusion annealing stabilizes the polymer to minimize residual stress, and quality control checks (dimensional verification, pressure testing, and visual inspection) ensure conformity.

Build Quality Factors

- Dimensional consistency: Tight tolerances on bore and wall thickness reduce pressure drop variability and ensure reliable fittings engagement.

- Surface finish: Homogeneous internal bore reduces flow disturbance and particulate accumulation; well-defined external coil minimizes unpredictable flattening.

- Color uniformity: Industrial-grade colorants and pigment loadings ensure long-term color stability for identification purposes.

- Quality controls: Batch testing for burst pressure, cyclic flex, and abrasion provides traceable performance data for critical installations.

Key Features

- Outstanding low-temperature flexibility: Remains pliable and functional at temperatures down to -40 °C or lower in select formulations, reducing the risk of brittle failure in cold climates.

- High abrasion resistance: TPU-based compounds and optimized surface hardness protect against wear in dynamic assemblies and contact-heavy applications.

- Chemical resistance: Compatibility with compressed air, many greases and oils, diluted acids and alkalis, and common cleaning agents. Certain solvents (e.g., strong ketones) should be avoided unless the specific compound is validated.

- Compact coiling: Small relaxed loop length reduces footprint and prevents snagging while providing rapid recovery after extension.

- Lightweight construction: Minimizes dynamic loading on moving parts and reduces overall assembly mass.

- Color options: Enables visual differentiation for media type, pressure class, or department-level segregation for safer operations.

- Multiple connector compatibility: Works with a wide range of push-in fittings, barbed fittings, and quick-disconnect couplers.

- Cost-effective: Economical price point relative to specialized braided hoses while delivering robust performance for pneumatic and low-pressure fluid handling.

Use Cases and Applications

Because of its combination of flexibility, abrasion resistance, and weather tolerance, the Individual Coil Hose is suitable for a broad set of applications across industries. The following subsections outline typical deployments where this hose provides significant advantages.

1. Industrial Automation and Robotics

Robotic arms and gantries require small-diameter, flexible hoses for pneumatic actuation, gripper vacuum lines, and instrument air. The coiled form reduces the chance of hoses dragging over equipment, simplifies routing near moving axes, and minimizes interference with adjacent tooling while providing sufficient extension for articulated movements.

2. Assembly Lines and Pneumatic Tooling

On production floors where hand-held pneumatic tools are used, coiled hoses allow operators a convenient reach without the hose trailing on the floor or getting tangled underfoot. Color-coding helps ensure appropriate tool-media matching and safe segregation of high-pressure air lines from other utilities.

3. Mobile Test and Diagnostic Equipment

Portable analyzers, tire inflation stations, and service carts benefit from coiled hoses that store compactly in confined toolboxes and extend easily when servicing equipment at variable distances.

4. Laboratories and R&D

Laboratory setups with compressed air manifolds, vacuum fixtures, or low-pressure fluid circuits can use these hoses for neat cable-routing and for rapid prototyping environments where temporary connections are often moved.

5. HVAC and Control Systems

Small-bore tubing for pneumatic controls in HVAC dampers and valves often requires flexibility for retrofit installations. The Individual Coil Hose enables compact routing and maintains functionality in cold rooms or ambient outdoor locations.

6. Packaging and Material Handling

Packaging machinery frequently uses vacuum-based pick-and-place fixtures and pneumatic grippers. Coiled hoses reduce interference with product flow and facilitate rapid replacement and reconfiguration during product changeovers.

Comparison with Similar Products

Below is a technical comparison between the Individual Coil Hose and common alternatives: standard nylon tubing, traditional polyurethane (non-coiled) tubing, and PVC coiled hoses. This table highlights the typical performance trade-offs engineers should consider when selecting a tubing solution.

| Attribute | Individual Coil Hose (TPU/TPE) | Nylon Tubing | Polyurethane (straight tubing) | PVC Coiled Hose |

|---|---|---|---|---|

| Low-temp flexibility | Excellent (-40 °C to +80 °C) | Poor to fair (brittle below ~0 °C) | Good (-30 °C to +60 °C) | Limited (-10 °C to +50 °C) |

| Abrasion resistance | High | Moderate | Good to high | Low to moderate |

| Chemical resistance | Good (many oils & oils, limited strong solvents) | Good (especially oil & fuel resistance) | Good (similar to TPU) | Poor to moderate (plasticizers can leach) |

| Flex life (cyclic) | High | Moderate (can fatigue under repeated flex) | Good | Moderate |

| Cost | Economical | Low to moderate | Moderate | Low |

| Ease of routing / storage | Excellent (coiled) | Poor (requires reels or slack) | Poor to fair | Good (if coiled but lower performance) |

| Typical applications | Pneumatic lines, robotic end-of-arm tooling, handheld tools | Hydraulic pneumatics, fuel lines, precision instrumentation | General pneumatics, machine lines | Consumer pneumatic kits, low-cost tool hoses |

Summary: The Individual Coil Hose outperforms nylon tubing in low-temperature flexibility and is often preferred over PVC coiled hoses where abrasion resistance and longevity are priorities. Compared with straight polyurethane tubing, the coiled geometry provides easier routing and storage for dynamic applications.

Benefits and Limitations

Benefits

- Space-saving: The compact coiled geometry significantly reduces storage footprint and the risk of hose entanglement.

- Improved durability: TPU/TPE compounds provide long service life under repeated flex and abrasion environments.

- Cold-weather performance: Proven pliancy at sub-zero temperatures expands the usable range relative to many alternatives.

- Easy identification: Multiple colors reduce installation errors and improve maintenance efficiency.

- Interchangeability: Compatible with widely used pneumatic fittings and coupling systems.

Limitations

- Pressure limitations: Designed primarily for low-pressure pneumatic and fluid handling; not suitable for high-pressure hydraulic service without reinforcement and validation.

- Chemical exposure: Although resistant to many chemicals, highly aggressive solvents (e.g., concentrated ketones, strong chlorinated hydrocarbons) can degrade thermoplastics; compatibility verification is required for unusual media.

- Stretch limits: Coiled hoses have a finite extension range; over-extension beyond specified maximums increases the risk of plastic deformation and reduced recovery.

- Service temperature caps: Upper temperature limits (~+80 °C typical) can be lower than some fluoropolymer hoses or metal tubing systems.

Maintenance and Care Guide

Proper maintenance prolongs service life and preserves safety margins. The following professional guidelines are recommended for routine care, inspection, and replacement planning.

Inspection Checklist

- Visually inspect hoses every 3 months in normal service (more frequently in harsh environments): look for cuts, abrasions, flattening of coils, discoloration, or softening.

- Check fittings and connectors for corrosion, secure engagement, and any sign of leaking at the interface.

- Confirm the hose is not overstretched relative to its rated maximum extension. Replace hoses that show permanent elongation or kinking.

- Perform a pressure test after any suspected mechanical impact or when a safety-critical line is put back into service.

Cleaning Procedures

Use mild detergents and warm water to clean external surfaces. Avoid prolonged exposure to strong solvents unless compatibility has been established. Rinse thoroughly and allow to air dry. For internal cleaning (if carrying fluids other than compressed air), flush with an appropriate solvent or cleaning fluid that is known to be compatible with the hose polymer, followed by deionized water to remove residues.

Storage

- Store coiled hoses in a cool, dry area away from direct sunlight and ozone sources (ozone exposure can accelerate polymer degradation for some compounds).

- Avoid compressive loads on coiled hoses during storage to prevent permanent deformation of the coil geometry.

- Maintain temperatures within the recommended storage range (typically +5 °C to +25 °C for best shelf-life).

Replacement and Lifespan

Typical service life depends on application and duty cycles. Under moderate usage, Individual Coil Hoses often serve for several years; however, warranty and expected life should be determined from field data and supplier documentation. Replace hoses immediately if:

- Permanent elongation or deformation is observed;

- Surface cracking, hardening, or severe abrasion exposes inner layers;

- Leaks develop at fittings or along the length;

- Any chemical exposure results in softening, swelling, or discoloration indicative of compound degradation.

Installation Best Practices

Proper installation reduces premature failures and system downtime. Key installation recommendations follow:

- Select correct fittings: Use push-in pneumatic fittings for ease of assembly and vibration tolerance. For higher mechanical retention, use barbed fittings with properly sized clamps or serrated ferrules.

- Guard against twisting: During assembly, minimize torsion on the hose. Torsion can accelerate fatigue and lead to fitting failure.

- Avoid sharp edges: Route hoses away from sharp flanges or edges; where unavoidable, apply protective sleeving or abrasion guards.

- Respect minimum bend radius: Maintain at least the manufacturer’s recommended minimum bend radius at routing bends and at the fitting interface; tighter bends increase stress and reduce flow performance.

- Accommodate thermal movement: Where temperature variations are expected, allow for thermal expansion and contraction; do not clamp the hose rigidly at multiple points without considering differential movement.

- Label critical lines: Use the color-coding and supplementary labeling to identify media and operating pressures for maintenance and safety audits.

Testing and Quality Assurance

Manufacturers of reputable Individual Coil Hoses perform a suite of tests to verify performance and safety. Common tests and QA processes include:

- Burst pressure testing: Each batch is tested to a defined multiple of the working pressure (commonly 3:1 or 4:1 safety factor) to ensure integrity under pressure spikes.

- Cyclic flex testing: Repetitive bend tests at specified radii to quantify flex life and monitor for crack initiation or performance degradation.

- Abrasion testing: Standardized abrasion tests to provide a measure of wear resistance and predict lifetime under sliding contact conditions.

- Dimensional verification: Gauge checks on I.D., O.D., wall thickness, and coil pitch to assure interchangeability and fitment accuracy.

- Chemical exposure tests: Immersion or exposure panels to determine resistance to specific fluids encountered in target markets.

- Leak and pressure-hold tests: 100% or sample-based tests to detect pinholes and manufacturing defects.

When procuring hoses for critical systems, request manufacturer test reports and lot traceability data. For safety-critical installations, third-party certification or independent testing may be required.

Ordering, Customization, and Color Coding

Individual Coil Hoses are typically offered in a standard set of colors (e.g., blue, black, red, yellow, green, clear/translucent) and in a range of diameters and coil geometries. Custom options commonly available include:

- Special compound formulations for specific chemical compatibilities or higher temperature ratings.

- Custom coil pitch and outer diameter for unique storage or extension requirements.

- Pre-assembled with fittings and custom lengths for drop-in installation.

- Printed legends for identification (part numbers, flow direction, or safety markings).

Ordering considerations:

- Specify nominal I.D. and O.D. along with desired relaxed and extended lengths to ensure the hose meets routing requirements.

- Confirm compatibility with process media and expected operating temperatures.

- Decide whether to procure pre-assembled hose assemblies (with fittings and end treatments) or to purchase bulk hose and fit locally.

- Ask for material safety data sheets (MSDS) and compliance statements for RoHS, REACH, or other regional regulations if required.

Environmental and Regulatory Considerations

When selecting hoses for long-term deployment, consider environmental impact, regulatory compliance, and end-of-life handling:

- RoHS and REACH: Many suppliers provide compliant formulations that avoid restricted substances. Request declarations if required for European or other international markets.

- Recyclability: Thermoplastic materials can often be recycled at end-of-life subject to local recycling capabilities, though contaminated hoses (with oils, chemicals) may require special disposal.

- Ozone and UV exposure: Prolonged exposure can degrade certain elastomeric compounds; where exposure is unavoidable, specify UV-stabilized formulations.

- Medical and food-grade: Standard industrial compounds are not inherently food-grade or medical-grade. If the hose will contact potable water, foodstuffs, or medical gases, request certified food-contact or medical-grade materials and documentation.

Practical Design Considerations for System Engineers

When integrating Individual Coil Hoses into systems, engineers should account for several practical design factors to ensure performance and longevity:

- Pressure spikes: Use surge protection, pressure relief valves, and accumulators to limit transient spikes that can stress hose walls and fittings.

- Dynamic mass & inertia: Although lightweight, the hose – particularly when extended – contributes to moving mass. Account for this in motion control and tool balancing calculations.

- Fitting retention: Select fittings with tested pull-out and burst performance compatible with the hose’s wall thickness and compound.

- Routing redundancy: Avoid routing hoses along paths that expose them to pinch points or crush zones; provide slack loops or guiding tracks where repeated movement occurs.

- Serviceability: Design for easy replacement access to minimize downtime; consider quick-disconnect couplings in field-serviceable positions.

Case Study: Robotic End-of-Arm Tooling

Application: A manufacturer of small electronic devices requires pneumatic vacuum grippers on a multi-axis robotic arm. The hose must allow for repetitive motion across multiple axes, be compact to avoid entanglement with wiring, operate reliably in a climate-controlled cleanroom environment (5–25 °C), and be color-coded to distinguish vacuum and instrument air lines.

Solution: The manufacturer selects a 6 mm Individual Coil Hose with a TPU compound rated to -40 to +80 °C, assembled with low-profile push-to-connect fittings and protective sleeving at wrist joints. The coil geometry provides a 600 mm maximum reach sufficient for gripper travel while retracting compactly during rest cycles. Periodic flex tests and inspection intervals are established at 6 months for verification.

Outcome: The assembly experiences reduced downtime due to hose entanglements, simplified maintenance procedure for quick hose replacement, and improved safety and process control due to color-coded lines.

Frequently Asked Technical Questions (FAQ)

Q: Can the Individual Coil Hose be used for vacuum service?

A: Yes—many formulations are compatible with vacuum applications. Confirm the specific part’s collapse resistance and vacuum-rated performance. For high-vacuum or critical vacuum systems, test the part in the real application to verify acceptable leakage and collapse margin.

Q: What is the expected elongation/recovery after repeated extension?

A: Properly formulated TPU/TPE coiled hoses are designed to recover to near-original coil geometry after routine extension within the rated maximum. Permanent set may occur if hoses are repeatedly stretched beyond recommended limits or subjected to elevated temperatures while extended.

Q: Can the hose be sterilized or autoclaved?

A: Standard industrial compounds are not typically rated for autoclave sterilization (121 °C+). For medical or sterilizable applications, request materials specifically certified for those processes.

Q: How should fittings be attached to prevent leaks?

A: Use manufacturer-recommended fittings sized to the hose O.D. For push-to-connect fittings, ensure full insertion depth. For barbed fittings, use clamps or ferrules sized to the hose wall thickness; when using ferrules, match material hardness to the hose compound to prevent cutting or extrusion under pressure.

Conclusion

The Individual Coil Hose is a technically robust, cost-effective solution for a broad set of pneumatic and low-pressure fluid conveying applications. Its combination of exceptional low-temperature flexibility, strong abrasion and chemical resistance, lightweight construction, and compact coiled geometry makes it particularly well-suited for automation, tooling, laboratory setups, mobile equipment, and confined-space installations.

System designers benefit from the hose’s ease of routing and color-coding options, while maintenance teams appreciate its durability and simple inspection requirements. Engineers should select the appropriate nominal diameter, coil geometry, and material formulation for their specific operating environment and confirm chemical and temperature compatibility prior to deployment.

For critical applications, consult manufacturer datasheets, request batch test reports, and consider pre-assembled hose assemblies with certified fittings to streamline installation and reduce service risk. With proper selection and installation, the Individual Coil Hose provides a reliable, long-service-life solution that minimizes downtime and improves the ergonomics and safety of fluid distribution systems.

Contact your supplier or technical representative for detailed datasheets, material certifications, and bespoke configuration options tailored to your application.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.