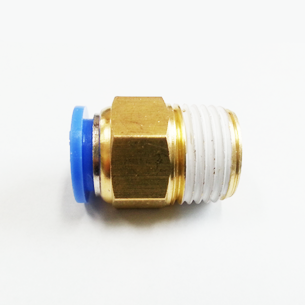

PC Male Straight — One-Touch Pneumatic Fitting for Fast, Reliable Compressed-Air Connections

PC Male Straight is a compact one-touch pneumatic fitting engineered for compressed-air systems where rapid, tool-free tube connections and minimal installation footprint are essential. Its hybrid hexagonal exterior and inner gripping geometry enable quick routing and tightening in confined spaces, while the one-touch collet and seal-coated threads provide leak-resistant joints with repeatable installation and maintenance performance. This article provides an in-depth technical overview of the PC Male Straight fitting, including specifications, materials, practical applications, installation best practices, maintenance, comparison with alternative fittings, benefits and limitations, and guidance for specifying the correct variant in pneumatic systems.

Introduction

Pneumatic systems are widely used across industrial automation, robotics, packaging, material handling, and laboratory equipment. A recurring installation and maintenance challenge in these systems is making frequent, reliable, and compact tube connections in tight spaces without introducing leaks or requiring specialized tools. The PC Male Straight one-touch pneumatic fitting addresses this challenge by combining a push-in tube interface with a male threaded end for direct integration into valves, manifolds, cylinders, and actuators.

This product is optimized for compressed-air applications and is engineered to simplify assembly, reduce downtime during servicing, and maintain long-term sealing performance under typical industrial pressures and temperatures. The one-touch mechanism allows insertion and release of tubing in 1–2 seconds, significantly reducing installation time in systems with numerous connections.

Technical Overview

The PC Male Straight is a push-in (or push-to-connect) fitting with a straight-flow geometry: one end accepts a flexible or semi-rigid pneumatic tube, and the other end provides a male threaded connection for mating with component ports. The fitting is available in a range of tube sizes (both metric and inch) and threaded types to accommodate international standards and common port types.

Key functional characteristics:

- One-touch tube connection: Rapid insertion and release via a spring-loaded collet and internal O-ring, enabling tool-free assembly/disassembly.

- Straight through flow path: Low pressure drop and straightforward routing when used in-line.

- Hexagonal external geometry: Dual hex (inner and outer) profile for wrench engagement in confined or hard-to-reach locations.

- Seal-coated threads: Threaded male end is supplied with a pre-applied seal coating to simplify sealing and reduce need for additional tape or sealant.

- Wide model matrix: Supports metric tubes (Φ4–Φ16) and inch tubes (5/32″–1/2″) with corresponding metric PT or imperial NPT thread options.

Functional Principle

When a tube is inserted into the push-in end, it bottoms against an internal stop. A collet containing hardened steel teeth or an engineered resin gripping ring retains the tube axially. A resilient O-ring or elastomeric seal around the tube diameter provides the gas-tight seal. To remove the tube, the user depresses the outer sleeve (collet) which retracts the retention element, allowing the tube to be withdrawn. This mechanism makes the connection both secure under pressure and easily releasable without tools.

Specifications and Dimensions

The following tables summarize the key technical specifications and the primary model variants available for the PC Male Straight fitting. All values are given as typical performance ranges; refer to manufacturer datasheets for certified values for a specific production lot.

General Performance Specifications

| Parameter | Specification |

|---|---|

| Intended fluid | Compressed air only |

| Operating pressure | 0–150 PSI (0–9.9 kgf/cm², 0–990 kPa) |

| Allowable vacuum | Down to −29.5 in Hg (−750 mm Hg) |

| Temperature range | 32–140 °F (0–60 °C) |

| Connection style | Push-in tube to male thread (straight) |

| Typical connection/disconnection time | 1–2 seconds (per end) |

| Sealing method | Elastomer O-ring (tube end) + seal-coated threads |

Model and Size Matrix

Sample model codes and common thread pairings:

| Model Code | Tube Size (Nominal) | Thread | Thread Type |

|---|---|---|---|

| PC 04-M5 | Φ4 mm | M5 × 0.8 | Metric (PT/M) |

| PC 06 1/8 | Φ6 mm | 1/8″ | PT / BSPP or 1/8″ NPT variant |

| PC 08-1/8 | Φ8 mm | 1/8″ | Compatible PT or NPT thread options |

| PC 12-1/8 | Φ12 mm | 1/8″ | Thread variant options |

| PC 5/32-U | 5/32″ | U-thread (imperial) | NPT/BSP compatible variants |

| PC 1/4-N1 | 1/4″ | 1/4″ | NPT / BSPP options |

| PC 3/8-N1 | 3/8″ | 3/8″ | NPT / BSPP options |

Typical Physical Dimensions (Representative)

Representative outer dimensions for common tube sizes are listed; actual values vary slightly by thread type and manufacturer. When specifying, consult the product drawing for exact dimensions.

| Tube Size | Overall Length (mm) | Thread Length (mm) | Hex Flats (mm) | Tubing Insertion Depth (mm) |

|---|---|---|---|---|

| Φ4 mm | 20–28 | 8–10 | 9–11 | 8–10 |

| Φ6 mm | 22–30 | 8–12 | 11–14 | 10–12 |

| Φ8 mm | 25–35 | 10–14 | 14–17 | 12–15 |

| Φ10 mm | 28–38 | 10–16 | 16–19 | 14–16 |

| Φ12 mm | 30–40 | 12–18 | 17–20 | 16–18 |

| Φ16 mm | 36–46 | 14–20 | 20–24 | 18–20 |

| 1/4″ (6.35 mm) | 22–32 | 8–12 | 11–14 | 10–12 |

| 1/2″ (12.7 mm) | 34–44 | 14–20 | 20–24 | 18–20 |

Materials and Build Quality

Material selection for pneumatic fittings is a balance between mechanical durability, corrosion resistance, manufacturability, cost, and compatibility with air and seal materials. The PC Male Straight fitting is typically constructed from the following materials and assembly features. Where multiple options exist, they are identified so engineers can choose the right variant for their application.

- Body material

- Common: Nickel-plated brass — offers a robust combination of corrosion resistance and mechanical strength for industrial environments.

- Alternative: Stainless steel (e.g., 303/304) — used for aggressive environments, washdown areas, or where higher chemical resilience is required.

- Lightweight option: Engineering plastics (e.g., PBT or modified nylon) — used in light-duty applications where weight and cost are primary concerns.

- Collet and sleeve

- Typically acetal (POM) or reinforced nylon — these high-performance thermoplastics provide low friction, dimensional stability, and wear resistance for repeated connections.

- Seals (O-rings)

- Standard: Nitrile (NBR) — offers excellent sealing for compressed air in the temperature range 0–60 °C.

- Optional: Fluoroelastomer (FKM/Viton) — for elevated temperature or chemical exposure when specified.

- Internal retaining elements

- Hardened stainless steel retaining teeth or engineered resin gripping surfaces depending on size and duty cycle.

- Thread sealing

- Factory-applied seal coating (liquid thread sealant) or pre-applied sealing tape on variants; this reduces variability in field sealing performance and minimizes torque-induced leaks.

Build quality considerations:

- Precision-machined seats and O-ring grooves ensure consistent sealing force and longevity.

- Surface finishes (nickel plating, passivation on stainless steel) reduce corrosion and galling on threaded connections.

- Collet tolerances are controlled to maintain gripping force without damaging tubing—especially important for soft polymer tubing.

Key Features

The PC Male Straight fitting integrates design features that make it suitable for a broad range of pneumatic installations. Each feature is highlighted below with technical context and the practical benefit it delivers.

- Instant tool-free operation — Push-in connection and release via the outer sleeve reduces assembly time and eliminates the need for wrenches during tube changes.

- Compact hexagonal profile — Inner and outer hex shapes enable wrench engagement when necessary and provide multiple gripping points for routing and tightening in constrained spaces.

- Seal-coated threads — Factory-applied thread seal reduces the risk of assembly leaks and ensures consistent torque/ sealing behavior across installations.

- Wide size and thread compatibility — Metric tube sizes and imperial tube sizes with corresponding thread choices (PT/BSPP/NPT) make the fitting suitable for global applications.

- High service pressure capability — Rated up to 150 PSI (990 kPa), which covers most industrial compressed-air systems.

- Vacuum capability — Usable down to −29.5 in Hg, enabling use in both positive pressure and vacuum-assisted applications within the specified temperature range.

- Rapid maintenance — In-system tube replacements take only seconds, minimizing downtime for troubleshooting or reconfiguration.

Use Cases and Applications

The PC Male Straight fitting is designed for compressed-air systems where speed, reliability, and compactness are required. Typical applications include, but are not limited to:

- Industrial automation — Pneumatic actuators, valves, and air cylinders used on assembly lines, pick-and-place machines, and CNC automation. The straight male fitting is ideal for direct porting into valve bodies or manifolds.

- Robotics — Lightweight pneumatic tubing connections for grippers, end-of-arm tooling, and vacuum cups where quick changes and low profile fittings are advantageous.

- Packaging and material handling — Conveyors, pneumatic sorters, and packaging equipment that require frequent maintenance or component swaps.

- Laboratory and life-science equipment — Benchtop instruments and gas delivery lines requiring clean, reliable air connections with minimal tools.

- Prototyping and R&D — Fast reconfiguration of pneumatic circuits in test rigs and experimental setups.

- HVAC and instrument service — For certain control air and pilot lines where small-diameter tubing connections are necessary.

Because the PC Male Straight is designed for compressed air, it should not be used for liquid hydraulic systems or with aggressive chemicals unless specifically qualified variants are supplied.

Comparison with Similar Products

When specifying fittings for pneumatic systems, engineers commonly weigh the trade-offs between push-in fittings, compression fittings, and threaded adapters. The table below compares the PC Male Straight fitting with common alternatives across several criteria.

| Attribute | PC Male Straight (One-Touch) | Standard Compression Fitting | Barbed Fitting with Hose Clamp | Quick-Disconnect Coupler |

|---|---|---|---|---|

| Connection method | Push-in one-touch collet | Compression nut and ferrule (tool required) | Barb + clamp (tool required for clamp) | Coupling with valve mechanism (tool-free) |

| Assembly speed | Very fast (1–2 sec) | Moderate (minutes) | Moderate (minutes) | Fast (seconds) |

| Reusability | High (many cycles) | High but ferrule life may limit cycles | Lower (clamp/hoses wear) | High (designed for repeated connect/disconnect) |

| Seal reliability | High for air systems (O-ring + collet) | High when properly installed | Moderate (clamp torque variability) | High (valved couplers included) |

| Footprint | Compact (hexagonal body) | Moderate | Bulky at clamp | Bulky |

| Tool requirement | None for tube change; wrench sometimes for thread | Wrench required | Clamp tool required | None |

| Best application | Control air, tight spaces, fast maintenance | Permanent or semi-permanent connections | Low-cost, low-pressure lines | Frequent connect/disconnect of air tools |

Summary: The PC Male Straight fits the niche of compact, fast, and reliable push-in fittings for compressed-air systems where threading into ports is required. It offers a stronger, more repeatable seal than barbed hose fittings and much faster serviceability than compression fittings while being smaller and less complex than multi-part coupler assemblies.

Benefits and Limitations

Benefits

- Speed and convenience — Rapid tool-free tubing insertion and release accelerate assembly and reduce downtime during maintenance.

- Compactness — Hexagonal body and straight geometry allow installation in confined or densely packed manifolds.

- Leak-resistant — Elastomeric seals and factory-applied thread sealant lower the probability of field leaks when properly installed.

- Versatile sizing — Broad range of tube and thread sizes supports global applications.

- Durability — Robust materials such as nickel-plated brass and POM collets provide a long service life under normal conditions.

- Vacuum-capable — Useful for systems that require vacuum levels as well as positive pressure.

Limitations

- Air only — These fittings are designed for compressed air. They should not be used with hydraulic oils, aggressive chemicals, or oxygen without explicit manufacturer approval.

- Temperature range — Standard seal materials restrict operation to 0–60 °C (32–140 °F). Higher-temperature environments require special seal compounds.

- Tube compatibility — Push-in fittings are designed for specific tubing materials (polyurethane, nylon, polyethylene). Soft or non-standard tubes may deform and compromise the seal.

- Cycle life — Although designed for many cycles, extremely frequent connect/disconnect cycles or abrasive contaminants can reduce collet and seal life.

- Max pressure ceiling — With a 150 PSI rating, PC Male Straight fittings are not intended for higher-pressure pneumatic systems used in specialized industrial processes.

Installation and Maintenance Guide

Correct installation and periodic maintenance are critical to achieving long-term performance. The following professional guidelines are intended for technical staff and engineers installing or servicing PC Male Straight fittings.

Pre-Installation Checks

- Confirm that the fitting material and seals are compatible with the operating environment and intended fluid (compressed air only).

- Verify tube outer diameter and wall thickness against the fitting’s specified tube size and insertion depth. Use tubing rated for the system operating pressure.

- Inspect threads on mating ports for damage or contamination. Clean debris and old sealant prior to assembly.

- Ensure thread variant (PT/BSPP/NPT) matches the port; do not force mismatched thread types.

Installation Procedure

- Hand-start the threaded end into the mating port. Tighten by hand to ensure correct thread engagement and to prevent cross-threading.

- If a torque value is specified by the manufacturer, apply a calibrated torque wrench to the hex flats and tighten to the recommended torque. Typical small fittings may require low torque values; avoid over-tightening (over-tightening may crack plastic bodies or deform threads).

- Route tubing to avoid excessive bending radii, abrasion, or kinks. Maintain recommended minimum bend radius for the tubing material.

- To insert tubing into the push-in end: fully insert the tubing until it bottoms out against the internal stop. Pull lightly to verify retention. Connection is secure when the tube resists axial pull without sleeve collapse.

- To disconnect: depress the outer sleeve evenly and withdraw the tube straight out. Do not use twisting motions or side loading when depressing the sleeve.

- Perform a pressure leak test: bring the system to operating pressure, apply soapy water or an approved leak detection fluid to the connection, and inspect for bubbles. If bubbles appear, repressurize and check thread torque and tube seating.

Routine Maintenance

- Inspect push-in fittings visually and by hand for any sign of polymer degradation (cracks, discoloration), corrosion on metal surfaces, or permanent tube deformation.

- Replace O-rings and collet elements when leaks appear or when repeated connect/disconnect cycles have increased play or reduced retention force.

- Keep the sealing surfaces and tubes clean—contaminants such as dirt, metal shavings, or chemical residues can cause leaks or accelerated wear.

- Do not lubricate the sealing elements with incompatible lubricants. Use manufacturer-recommended lubricants if necessary for assembly of specific seal materials.

- Periodic functional tests: verify sealing under operating pressure and vacuum conditions and monitor for pressure decay in closed circuits.

Troubleshooting Guide

- Leak at the push-in connection:

- Confirm tube fully inserted and not cut at an angle. Re-cut tube squarely with a tube cutter and reinsert.

- Inspect O-ring for damage; replace if necessary.

- Check tube outer diameter—if tubing has expanded or reduced, it may no longer fit correctly.

- Leak at the thread:

- Inspect threads for cross-threading or damage. Reapply thread sealant and torque to recommended value.

- If threading surfaces are worn or stripped, replace the fitting or the mating component.

- Tube releases unexpectedly:

- Check collet teeth or gripping ring for wear. Clean or replace the collet assembly if it has debris or wear.

- Ensure tubing is not lubricated (accidental grease/oil contamination can reduce grip).

- Difficulty inserting tubing:

- Verify the tubing inner dimension/hardness; some tubing requires a chamfered end or small leading taper to ease insertion.

- Inspect collet sleeve for foreign bodies or deformation.

Specification and Selection Checklist

When selecting a PC Male Straight fitting for an application, use the following checklist to ensure the component meets system requirements:

- Confirm operating pressure and vacuum requirements fall within the fitting rating (0–150 PSI, down to −29.5 in Hg).

- Select tube size that matches the tube OD precisely (Φ4, Φ6, Φ8, Φ10, Φ12, Φ16 or imperial sizes listed).

- Choose the correct thread type for the mating port (M5, 1/8″, 1/4″, 3/8″, 1/2″, PT, BSPP, or NPT as applicable).

- Check material compatibility: brass vs. stainless steel, and seal compound (NBR vs. FKM) for temperature and chemical compatibility.

- Confirm physical clearance and wrench access for hex flats; verify required torque values from the manufacturer.

- Assess number of expected connect/disconnect cycles and environmental exposure (corrosive atmospheres may require stainless or plated materials).

Practical Examples and Application Notes

Below are a few practical scenarios where PC Male Straight fittings offer particular advantages:

Example 1: High-Density Valve Manifold Installation

An OEM is designing a pneumatic manifold to control multiple cylinder banks. Space is constrained and high-density porting is necessary. By specifying PC Male Straight fittings with the compact hex profile, the design team can mount fittings closely together while still allowing a wrench to tighten them during assembly. The push-in tube ends permit quick routing of small-diameter tubing runs and allow field technicians to replace tubing without dismantling the manifold.

Example 2: Robotic End Effector

Robotic grippers often require small pneumatic lines routed through a wrist joint. The PC Male Straight fitting’s compact straight form and one-touch tube connection enable technicians to replace or re-route tubing quickly during maintenance without disassembling the gripper or removing the robot from service for extended periods.

Example 3: Test Lab Reconfiguration

In test labs, pneumatic test rigs are frequently reconfigured for new experiments. Using PC Male Straight fittings allows researchers to swap tube runs and change pneumatic components rapidly, significantly reducing setup time between experiments.

Regulatory and Safety Considerations

- These fittings are intended for compressed air only. Do not use for oxygen service, gaseous fuels, or hazardous medical gases unless explicitly rated.

- Follow machine safety standards when altering pneumatic circuits (lockout/tagout, depressurization prior to maintenance).

- Comply with local standards for threaded fittings—note differences between PT/BSPP and NPT thread forms when ordering or installing fittings across regions.

- Use manufacturer-recommended sealants and torque specifications to avoid over-tightening or thread galling.

Comparative Performance Summary

To help engineers quickly assess whether the PC Male Straight is appropriate for a project, the summary below lists key performance attributes relative to common application requirements:

- Pressure handling: Suitable for standard industrial compressed-air systems up to 150 PSI.

- Serviceability: Excellent—rapid tool-free tube handling allows frequent maintenance.

- Footprint: Small—beneficial in dense installations.

- Durability: High for general industrial use, especially where brass/nickel-plated bodies and POM collets are selected.

- Environmental robustness: Good in typical indoor industrial settings; choose stainless or special seals for corrosive or high-temperature environments.

Ordering Guide and Part Number Examples

Typical product code convention: PC + tube size code + thread designation. Examples:

- PC 04-M5 — Φ4 mm tube to M5 thread

- PC 06 1/8 — Φ6 mm tube to 1/8″ thread

- PC 08-1/8 — Φ8 mm tube to 1/8″ thread

- PC 12-1/8 — Φ12 mm tube to 1/8″ thread

- PC 5/32-U — 5/32″ tube to U-thread (imperial)

- PC 1/4-N1 — 1/4″ tube to 1/4″ NPT/BSP variant (specify thread type)

- PC 3/8-N1 — 3/8″ tube to 3/8″ thread

When ordering, provide the following specification set to ensure correct fulfillment:

- Tube outer diameter (exact nominal)

- Thread size and standard (e.g., 1/8″ NPT, 1/8″ BSPP/PT, M5, etc.)

- Material preference for body (nickel-plated brass, stainless steel, plastic)

- Seal material (standard NBR or FKM for higher temperature / chemical resistance)

- Intended operating pressure and temperature

- Quantity and any packaging or traceability requirements

Conclusion

The PC Male Straight one-touch pneumatic fitting is a versatile, compact, and serviceable solution for compressed-air connections in industrial automation, robotics, packaging, laboratory setups, and other pneumatic systems. Its one-touch operation, compact hexagonal profile, and pre-applied thread sealing streamline installation and maintenance while providing reliable performance within the typical operating envelope of 0–150 PSI and 0–60 °C.

Engineers should select the correct tube and thread sizes, confirm material and seal compatibility, and follow best practices for installation and maintenance to maximize service life and system reliability. When speed of assembly, ease of maintenance, and compact porting are priorities, the PC Male Straight fitting offers clear technical and operational advantages compared to more traditional compression or barbed solutions.

If you need assistance selecting the correct model for your specific system (tube type, thread standard, material preferences, or operating conditions), provide your system parameters and we can recommend exact part numbers, installation torque values, and compatible tubing materials for optimal performance.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.