Polyurethane Coil Hose (UC C): Technical Guide for Industrial Automation and Pneumatic Systems

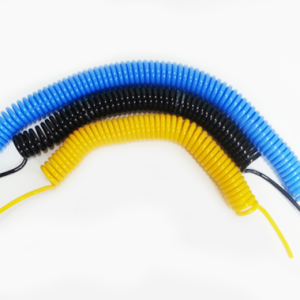

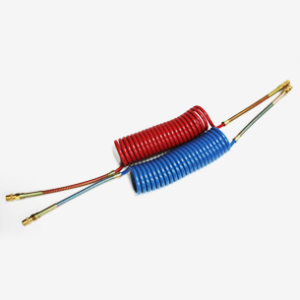

Product: Polyurethane Coil Hose (UC C)

Manufacturer: JISAN HOSETECH

Short description: Lightweight polyurethane coil hose designed for industrial automation and pneumatic tools. Offers excellent low-temperature impact resistance and mechanical durability. Available in multiple sizes and colors for use with robots, pneumatic equipment, centralized lubrication systems and air tools.

Introduction

The Polyurethane Coil Hose (UC C) series from JISAN HOSETECH is a purpose-built pneumatic coil hose family engineered for demanding industrial applications. These hoses combine the mechanical resilience and abrasion resistance of thermoplastic polyurethane (TPU) with the handling advantages of a coiled geometry, producing a compact, lightweight, and low-memory hose ideally suited for automated systems, robotic end‑effectors, tool stations, and centralized lubrication/air distribution networks.

This article provides a comprehensive technical overview of the UC C polyurethane coil hose line, including detailed specifications, materials and build quality, typical applications, installation and maintenance guidance, and a technical comparison with alternative coil hose technologies. The content is intended for design engineers, maintenance professionals, procurement specialists and system integrators who require in-depth technical information to specify and deploy coil hoses within pneumatic systems.

Technical Overview

The UC C series is manufactured from a high-performance thermoplastic polyurethane compound formulated to achieve high tensile strength, excellent abrasion resistance, and superior low‑temperature impact resistance. The hoses are extruded and then coiled to produce a compact retracted geometry that minimizes space requirements and reduces tripping and entanglement hazards in work cells.

Key mechanical and functional attributes of the UC C series include:

- Coiled form factor: Provides a compact retracted length for tidy routing and automatic extension/retraction during tool movement.

- Lightweight construction: Minimizes added inertia on robotic end-of-arm tooling (EOAT) and reduces dynamic load on moving elements.

- Outstanding low-temperature performance: TPU formulation maintains flexibility and impact resistance at low ambient temperatures down to -40°C.

- High mechanical durability: Abrasion resistant and resistant to repeated flexing and bending cycles typical of automated systems.

- Multiple nominal sizes and color options: Allows system organization, visual identification and optimized flow capacity.

The UC C line includes model families commonly designated JPC08-, JPC10- and JPC12- with length suffixes -50, -75 and -100. These designators reference nominal diameter families and collapsed coil lengths. The series is rated to a standard working pressure of 9.9 kg/cm² (approximately 0.97 MPa) with appropriate fittings and assembly practices.

Specifications and Dimensions

The following specification table presents typical, application-oriented mechanical and dimensional data for the most common UC C variants. Values are representative of JISAN HOSETECH production tolerances; for precise dimensional drawings and certified test reports, refer to the manufacturer’s technical datasheets and sample testing.

| Model | Nominal ID (mm) | Nominal OD (mm) | Wall Thickness (mm) | Collapsed Coil Length Options | Typical Max Extension (approx.) | Weight (g/m) | Min Bend Radius (mm) | Working Pressure (MPa) | Burst Pressure (MPa) | Operating Temperature Range | Available Colors |

|---|---|---|---|---|---|---|---|---|---|---|---|

| JPC08-50 / -75 / -100 | 4.0 | 8.0 | 2.0 | 0.5 m / 0.75 m / 1.0 m | 3.0 m / 4.5 m / 6.0 m | ~45 g/m | 25 | 0.97 | 2.9 (typical, 3× WP) | -40°C to +80°C (continuous) | Black, White, Blue, Red, Green, Yellow |

| JPC10-50 / -75 / -100 | 6.0 | 10.0 | 2.0 | 0.5 m / 0.75 m / 1.0 m | 2.5 m / 3.75 m / 5.0 m | ~60 g/m | 35 | 0.97 | 2.9 (typical) | -40°C to +80°C (continuous) | Black, White, Blue, Red, Green, Yellow |

| JPC12-50 / -75 / -100 | 8.0 | 12.0 | 2.0 | 0.5 m / 0.75 m / 1.0 m | 2.0 m / 3.0 m / 4.0 m | ~75 g/m | 50 | 0.97 | 2.9 (typical) | -40°C to +80°C (continuous) | Black, White, Blue, Red, Green, Yellow |

Notes on the table: Collapsed coil lengths (-50, -75, -100) indicate the nominal retracted lengths supplied. Maximum extension values are approximate, derived from typical coil pitch and diameter for each nominal size. Burst pressure is provided as a representative 3× safety factor over working pressure; certified burst pressures should be validated with the manufacturer for critical applications.

Materials and Build Quality

The UC C coil hose family is produced from a high-performance thermoplastic polyurethane (TPU) compound specifically formulated for pneumatic hose applications. TPU is a block copolymer consisting of alternating soft and hard segments that confer a balance of elasticity, toughness and abrasion resistance—properties that are essential for coil-type pneumatic hoses which are frequently flexed, pulled and exposed to abrasive surfaces in industrial environments.

Key material attributes include:

- High tensile strength: Typical TPU tensile strength values range from 40–60 MPa, delivering resistance to elongation under pressure and mechanical tear.

- High elongation at break: Many TPU elastomers achieve 300–600% elongation, allowing significant stretch before failure—an important property for coiled hoses that must uncoil and return repeatedly.

- Abrasion resistance: TPU exhibits one of the highest abrasion resistance ratings among thermoplastic elastomers, increasing service life under abrasive contact and sliding loads.

- Low-temperature flexibility: The UC C compound maintains flexibility and impact resistance at low temperatures (down to -40°C), limiting stiffness and brittleness in cold environments.

- Chemical resistance: TPU provides good resistance to oils, greases, hydraulic fluids and many common industrial contaminants. It is less resistant to strong acids, concentrated bases and aggressive ketones/esters—selection must be validated against the specific process fluids in the user’s environment.

Manufacturing and quality control measures for UC C hoses typically include continuous extrusion under controlled thermal profiles, precision coiling (to maintain consistent pitch and coil diameter), and post-production testing such as pressure proof tests, burst testing (sample-based or per batch) and dimensional inspection to ensure consistent mechanical performance and interchangeability with standard pneumatic fittings.

Key Features

The UC C polyurethane coil hose offers a set of features focused on performance in automation and pneumatic tool applications. Below is a categorized list of those features with technical rationale.

Mechanical and Performance Features

- High abrasion resistance: Superior wear life in sliding contact and multi-axis movement areas.

- Low-temperature impact resistance: TPU formulation prevents stiffening in cold climates or refrigerated environments.

- High hoop strength: Maintains cross-sectional stability under pressure, reducing kinking and inner-diameter collapse.

- Lightweight: Low mass per meter reduces dynamic loads on robotic arms and moving gantries.

- Extended service cycles: Durable under repeated flexing and extension cycles common to EOAT and tool-change operations.

Design and Usability Features

- Coiled geometry: Compact footprint, intrinsically retracted when not in use, reducing cable management complexity.

- Color-coding: Six color options (black, white, blue, red, green, yellow) simplify system layout, fault diagnosis and maintenance.

- Compatibility with standard fittings: Designed for push-in and screw-type pneumatic fittings used across automation equipment vendors.

- Multiple diameter options: JPC08, JPC10, JPC12 allow selection of internal flow capacity aligned with tool air consumption.

Use Cases and Applications

The UC C polyurethane coil hose is purpose-built for applications where compactness, dynamic handling and reliable pneumatic conveyance are required. Typical application domains include:

Industrial Robotics and Automated Assembly

Robotic arms, collaborative robots (cobots) and end‑effectors often require low mass and flexible routing for air supply to grippers, vacuum suction cups, and pneumatic actuators. UC C hoses reduce inertia and provide reliable air delivery through repetitive cycles and compact motion envelopes. Color coding can be used to differentiate circuits (e.g., vacuum vs. compressed air) or supply lines for multiple tools on an EOAT.

Pneumatic Tools and Hand tools

Coil hoses are commonly used on bench tool reels and mobile tool carts. The UC C series provides sufficient flow for light- to medium-duty air tools while minimizing hose drag and trip hazards due to its retracted geometry. Typical tools include air screwdrivers, sealant guns, blow guns and small impact drivers.

Centralized Lubrication and Air Distribution Systems

Where point-of-use distribution requires short runs from a bulk header to local valves or lubricators, coiled hoses minimize clutter. The TPU construction is compatible with many lubricants and oil mists encountered in automated lubrication systems; however compatibility should always be validated against the lubricant’s chemical composition.

Pick-and-Place and Packaging Machinery

High-cycle pick-and-place equipment requires hoses that will survive repetitive flexing and abrasion from localized contact. The UC C design mitigates early failures and reduces downtime due to hose replacement.

Mobile and Portable Equipment

The compact coil arrangement makes UC C suited for portable workstations and mobile diagnostic rigs where reel space is limited and quick deployment/retraction is needed.

Hydraulic/Pneumatic Performance Considerations

When selecting a coil hose for a pneumatic circuit, engineers should evaluate pressure drop, flow capacity, and dynamic behavior during extension and retraction. The UC C models provide adequate flow for most tool-level applications; however, system-level considerations include:

- Effective ID and pressure drop: Smaller internal diameters increase pressure drop at higher flow rates—choose JPC12 for applications requiring higher volumetric flow.

- Dynamic length changes: As the coil extends, the effective path length increases and transient pressure changes may occur—design regulators and control valves accordingly.

- Fitting selection: Use fittings with low flow restriction and proper thread/seal compatibility to maintain system performance.

Comparison with Similar Products

Below is a technical comparison of UC C polyurethane coil hoses versus common alternative coil materials: PVC, rubber-lined coil hoses and nylon (polyamide) tubing. This table highlights critical selection attributes.

| Attribute | UC C (Polyurethane) | PVC Coil Hose | Rubber Coil Hose | Nylon (Polyamide) Tube |

|---|---|---|---|---|

| Abrasion resistance | High | Moderate | Good | Moderate |

| Low-temperature flexibility | Excellent (-40°C) | Poor to Moderate | Moderate | Poor below 0°C |

| Weight | Light | Light to Moderate | Heavier | Very Light |

| Pressure rating (typical) | Up to ~1.0 MPa (working) | Lower (depends) | Comparable or lower | High for small diameters |

| Flex life (cycles) | Long (high) | Lower | Moderate | Variable; can be brittle |

| Chemical resistance | Good to many oils & greases; limited to strong solvents | Good to water/air; limited solvents | Good to oils; limited ozone resistance | Good resistance to many fluids; can be hydrolyzed under some conditions |

| Cost | Moderate | Low | Moderate | Moderate to high |

| Best use | Robotics, EOAT, tool reels, cold environments | General-purpose pneumatic lines | High-durability applications with lower flexibility demands | High-pressure small-bore pneumatic circuits |

Benefits and Limitations

Benefits

- Compact storage: Coiled form keeps hoses tidy and reduces the need for retraction reels or complex management systems.

- Reduced dynamic load: Lightweight construction reduces added mass on moving assemblies—important for high-speed pick-and-place and robotic arms.

- Resilience in cold environments: TPU compound remains flexible at low temperatures, preventing stiffening and cracking.

- High abrasion and flex resistance: Long service life in multi-cycle applications.

- Color coding: Simplifies installation, troubleshooting and maintenance operations.

- Compatibility with standard fittings: Easy integration into existing pneumatic systems.

Limitations

- Flow capacity limits: Coiled hoses have limited internal area relative to straight hoses of the same nominal size; for high flow or high-demand tools, larger bore or straight runs may be necessary.

- Extension limits: Coiled hoses are designed for short, controlled extensions; continuous full extension under load can accelerate wear and reduce life.

- Chemical exposure limitations: While TPU resists many industrial contaminants, exposure to aggressive solvents (e.g., strong ketones, MEK, concentrated acids) can degrade material integrity—chemical compatibility must be verified.

- Temperature ceiling: Continuous use above +80°C can accelerate aging; not recommended for sustained high-temperature applications without verification.

Installation, Handling and System Integration

Proper installation and handling significantly influence coil hose life and system reliability. The following guidelines are intended for system integrators and maintenance technicians.

Pre-installation checks

- Verify the selected model’s internal diameter and flow capacity meet the tool or actuator’s air consumption requirements considering pressure drop across fittings and regulators.

- Confirm working pressure and burst pressure margins are adequate for system maximum pressure, including pressure spikes and start-up transients.

- Validate chemical compatibility between the hose material and any fluids it may encounter during normal operation.

- Select fittings rated for the UC C hose’s OD and ensure thread and seal compatibility (NPT, BSP, metric, push-in style, etc.).

Routing and securing

- Avoid sharp bends that approach the nominal minimum bend radius specified in the product table. Localized kinking greatly reduces flow capacity and accelerates fatigue.

- Use strain relief at fittings and at points of high movement; swivel connectors or rotary unions can reduce torsional stress on the hose.

- Keep coiled hoses clear of pinch points, rotating tooling, and moving conveyors where abrasion and impact are likely.

- For robotic applications, route the hose to minimize interference with joint ranges of motion; provide slack at joints rather than tight bends.

Fitting installation

- Cut hose squarely with a fine-toothed blade or hose cutter to ensure full insertion into push-in fittings.

- For screw fittings, ensure thread sealant (tape or liquid sealant) is compatible with the hose compound and pneumatic system requirements.

- When using push-in fittings, verify insertion stop engagement and perform a pull-test to confirm retained connection strength in the expected load direction.

System testing

- Perform a pressure proof test at 1.5× working pressure to verify assembly integrity (where safe and appropriate).

- Perform leak detection (soapy water or electronic leak detector) at all joints.

- Cycle the hose through its expected motion profile under air pressure to simulate real-world operation and detect early mechanical interference issues.

Maintenance and Care Guide

Routine inspection and preventative maintenance will ensure long service life for the UC C coil hoses. The following maintenance actions are recommended for industrial environments.

Inspection frequency

- High-cycle robotic applications: visual inspection weekly; functional inspection (pressure and flow checks) monthly.

- Moderate-use applications (bench tools, mobile carts): visual inspection monthly; functional inspection quarterly.

- Low-use or static installations: visual inspection quarterly to bi-annually.

Inspection checklist

- Check for cuts, abrasions, or material degradation along the hose length—focus on high-contact points and near fittings.

- Check for visible kinks, flattening or localized deformation.

- Inspect fittings for corrosion, thread damage and secure seating.

- Listen for hissing or use leak detection to identify micro-leaks.

- Confirm coil memory—if hose remains permanently elongated or does not recover, consider replacement.

Cleaning

- Clean with mild soap and water or a neutral pH cleaner; avoid aggressive solvents that may attack the TPU compound.

- Rinse thoroughly and allow to dry before re-pressurizing the line.

Repair and replacement

- Small external abrasions that do not penetrate the hose wall can be monitored; however, any penetration or signs of internal delamination require immediate replacement.

- Do not attempt to splice coiled hoses for pressure applications—replace the entire segment to maintain burst and working pressure ratings.

- Replace hoses that exhibit permanent deformation (loss of coil memory), frequent leaks, or significant surface cracking.

Storage

- Store coiled hoses in a shaded, cool, dry environment away from direct sunlight and ozone sources (e.g., electric motors) to prevent oxidative degradation.

- Avoid stacking heavy objects on coiled hoses to prevent permanent deformation of the coil geometry.

Quality, Testing and Certification

JISAN HOSETECH performs production and batch-level quality controls to ensure dimensional consistency, pressure integrity and mechanical durability. Typical quality processes include:

- Dimensional checks (ID, OD, wall thickness)

- Proof pressure testing at a specified overpressure (e.g., 1.5× WP)

- Destructive burst testing on sample units per lot

- Visual inspection for extrusion defects and surface quality

- Physical property testing of the TPU compound (tensile strength, elongation, hardness)

End users requiring certified test reports, material certificates or customized test protocols (e.g., cyclic flex testing to a specified number of cycles) should consult JISAN HOSETECH to obtain factory test documentation and, if necessary, arrange third-party validation for safety‑critical applications.

Selection Checklist: Choosing the Right UC C Model

To select the appropriate UC C variant for your application, evaluate the following parameters:

- Volumetric flow requirement: Calculate required airflow (SCFM / L/min) at operating pressure and choose a nominal ID that produces acceptable pressure drop.

- Working pressure and potential spikes: Ensure the standard working pressure (0.97 MPa) is suitable and confirm margin against transient spikes or surge events.

- Dynamic extension needs: Choose a collapsed length (-50/-75/-100) that supplies sufficient reach when extended without over-stretching the coil.

- Environmental temperature: Confirm the operating temperature range (-40°C to +80°C continuous) is adequate for your application.

- Chemical exposure: Review fluid compatibility with the TPU material; request material compatibility data if exposure to unusual chemicals is expected.

- Fitting compatibility: Select fittings and adaptors compatible with the hose OD and the system’s connection standards.

Practical Example Configurations

Example 1 – Robotic Gripper Supply Line:

- Application: Air supply to parallel gripper on a six-axis robot used in cold storage (ambient -30°C).

- Recommended model: JPC08-75 (collapsed 0.75 m; extended ~4.5 m), black or blue for identification.

- Rationale: Small ID sufficient for gripper actuation, excellent low-temperature flexibility, lightweight to minimize EOAT mass.

- Fittings: Swivel push-in fitting at robot wrist to reduce torsional stress; bulkhead fitting at fixed manifold.

Example 2 – Tool Cart Workstation:

- Application: Multiple light air tools (blowgun, pneumatic screwdrivers) from a single reel.

- Recommended model: JPC10-50 or JPC12-50 depending on flow demands (JPC12 for higher-flow tools).

- Rationale: Compact coil reduces floor clutter; larger ID provides higher flow capacity when tools are used simultaneously.

- Fittings: Quick-disconnect couplers and a pressure regulator at the source to match tool requirements.

Troubleshooting Guide

Common issues and corrective actions when using coil hoses in pneumatic systems:

- Issue: Excessive pressure drop / weak tool performance

Corrective actions: Verify hose ID and length; switch to a larger nominal ID (e.g., JPC12); check for partial obstructions; ensure fittings are not restricting flow. - Issue: Hose does not fully retract or remains elongated

Corrective actions: Check for plastic deformation or over-extension history; confirm coil not trapped under equipment; replace hose if permanent deformation is present. - Issue: Abrasion at contact points

Corrective actions: Reroute hose to eliminate contact with abrasive surfaces or install protective spiral wrap or abrasion guards at affected points. - Issue: Repeated leaks at fittings

Corrective actions: Verify correct connector type, seating depth for push-in fittings, correct thread sealing for screw fittings, and consider using a swivel to reduce cyclical torque.

Lifecycle and Total Cost of Ownership

When compared with generic PVC or rubber coil hoses, the UC C polyurethane coil hose typically offers a longer operational lifespan under cyclic loading conditions—often translating to reduced replacement frequency, lower downtime, and decreased total cost of ownership (TCO) for high-cycle automated systems. The upfront cost may be modestly higher than some low-cost PVC alternatives, but durability, lower maintenance and improved uptime often justify the premium in industrial environments.

Regulatory and Safety Considerations

Always follow local regulations and internal safety protocols when installing pressurized hoses. Key safety practices include:

- Never exceed the rated working pressure of the hose and fittings.

- Ensure that pressure relief devices and regulators are set to prevent pressure spikes above safe limits.

- Protect personnel from moving parts and potential whipping of pressurized hoses by using appropriate hose leaders and restraints.

- Use personal protective equipment (PPE) during installation and maintenance as appropriate for the facility.

Ordering and Customization Options

JISAN HOSETECH offers the UC C series in stocked color and length variants as specified above, and can supply custom cut lengths, pre-assembled fittings, or batch-validated parts for OEM contracts. Common custom options include:

- Pre-assembled fittings (swivel, check valves, quick disconnect valves)

- Custom collapsed lengths and coil diameters for unique routing constraints

- Printed identification or numbering for inventory tracking

- Packaging and kitting for OEM installation lines

Conclusion

The Polyurethane Coil Hose (UC C) from JISAN HOSETECH is a technically robust and versatile solution for pneumatic distribution where compactness, durability and low-temperature performance are required. Its TPU construction delivers exceptional abrasion resistance, long flex life and resistance to cold-impact—properties that make it particularly well suited for robotic end-of-arm tooling, pneumatic tool carts, packaging lines and centralized lubrication systems.

When specifying UC C hoses, engineers should carefully match nominal diameter, collapsed length and fitting types to the target application’s flow demands and motion profile. With standard working pressure of approximately 0.97 MPa and a typical burst safety factor, the UC C series offers a reliable balance between compact handling and pneumatic performance. Appropriate installation, routine inspection and preventative maintenance will maximize service life and minimize downtime, making UC C a technically sound investment in industrial pneumatic systems.

For certified performance documentation, dimensional drawings or customization requests, contact JISAN HOSETECH or an authorized distributor with your application parameters (pressure, flow, ambient temperature, and expected motion cycles) so that the optimal model and assembly options can be provided.

Keywords: polyurethane coil hose, UC C, JPC08, JPC10, JPC12, pneumatic hose, TPU hose, robotic air line, industrial automation, low-temperature impact resistance, coiled hose, JISAN HOSETECH

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.