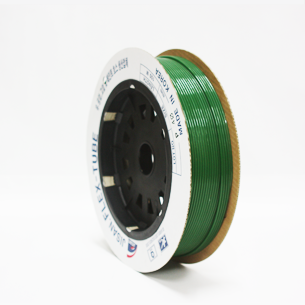

Polyurethane Round Belt (P-40, Shore ~92A) — Technical Guide and Specification

The Polyurethane Round Belt (P-40, Shore ~92A) is a high-performance flexible transmission and conveyor element engineered for demanding material handling, light conveyor, and power-transfer applications. Combining high tensile strength, excellent abrasion resistance, and robust chemical resistance to oils, greases and many solvents, this round-section polyurethane (PU) belt is designed to deliver long service life in dirty, dusty, or moisture-prone industrial environments. The product is supplied in standard diameters from 2 mm through 12 mm with custom sizes available on request, and requires a recommended initial installation tension of 3–5% of the installed wrap length for optimal performance.

Introduction

Round belts remain a compact, efficient solution for a variety of light- to medium-duty conveying, drive and indexing systems. The Polyurethane Round Belt in P-40 (approx. Shore 92A) is formulated specifically to address performance shortfalls commonly encountered with softer rubber belts — namely in tensile strength, abrasion resistance and resistance to oils and many industrial chemicals. This article provides a comprehensive technical overview for engineers, maintenance professionals and procurement specialists: specifications, mechanical properties, application use cases, installation and maintenance best practices, comparisons with alternative materials, and guidelines for design and selection.

Technical Overview

Polyurethane round belts are extruded or molded solid elastomeric rods that are supplied as continuous loops or cut to length and joined on-site. The P-40 grade used in this product is a highly cross-linked thermoset polyurethane compound with a Shore hardness of approximately 92A. Its formulation emphasizes:

- High tensile strength: the material exhibits elevated tensile and tear strength relative to softer elastomers, enabling smaller cross-sections to carry greater loads.

- Superior abrasion resistance: formulation resists wear from particulate contamination and repeated flexing over pulleys and idlers.

- Chemical resistance: stable in the presence of oils, greases and many common solvents encountered in production and processing lines.

- Low moisture uptake and dust resistance: geometry and material minimize contaminants adhering to the belt surface.

- Field-joinable: belts can be joined in place using a manual adhesive joining tool, avoiding the need for disassembly for many installations.

The belt is suitable for a wide range of systems: small-diameter drives, indexing mechanisms, part transfer and accumulation conveyors, light-weight packaging conveyors, and robotics where compact cross-section and durability are required.

How It Works and Typical Applications

A round belt transmits force by friction around pulleys, sheaves or crowned rollers. Because the contact area is defined by a circular cross-section, designers often use round belts where belt tracking, alignment simplicity and low-profile routing are priorities. The P-40 polyurethane compound increases allowable working loads and improves life under abrasive or chemically aggressive conditions compared with softer elastomeric belts.

Typical applications include:

- Precision part transfer and indexing in assembly lines

- Light conveyor belts in packaging (carton, pouch, small parcel handling)

- Drive belts for small motors, blowers and fans where compact size and reliability are needed

- Material handling in food processing equipment (contact approvals should be checked per application)

- Automated test equipment and laboratory automation

- Textile and printing equipment for fabric and web transport

Specifications and Dimensions

Below is a technical table listing the standard round diameters available for this product along with computed geometric and mechanical values. The calculations assume a polyurethane bulk density of approximately 1.20 g/cm³ and a nominal tensile strength of 50 MPa for the P-40 formulation. These values are intended as design guidance — for critical applications, supplier-provided test certificates and batch-specific test data should be used.

| Round Diameter (mm) | Cross-Sectional Area (mm²) | Mass per Meter (g/m) | Approx. Breaking Load (N) | Approx. Working Load (N) — SF = 8 | Approx. Working Load (kgf) | Recommended Min Pulley Dia (mm) | Preferred Pulley Dia (mm) |

|---|---|---|---|---|---|---|---|

| 2 | 3.142 | 3.77 | 157 | 19.6 | 2.0 | 16 | 20 |

| 3 | 7.069 | 8.48 | 353 | 44.2 | 4.5 | 24 | 30 |

| 4 | 12.566 | 15.08 | 628 | 78.5 | 8.0 | 32 | 40 |

| 5 | 19.635 | 23.56 | 982 | 122.7 | 12.5 | 40 | 50 |

| 6 | 28.274 | 33.93 | 1414 | 176.7 | 18.0 | 48 | 60 |

| 7 | 38.485 | 46.18 | 1924 | 240.5 | 24.5 | 56 | 70 |

| 8 | 50.266 | 60.32 | 2513 | 314.2 | 32.0 | 64 | 80 |

| 9 | 63.617 | 76.34 | 3181 | 397.6 | 40.5 | 72 | 90 |

| 10 | 78.540 | 94.25 | 3927 | 490.9 | 50.0 | 80 | 100 |

| 12 | 113.098 | 135.72 | 5655 | 706.9 | 72.0 | 96 | 120 |

Notes on the table:

- Cross-sectional area = π × (d²) / 4.

- Mass per meter is estimated using PU density ≈ 1.20 g/cm³ (volume per meter in cm³ equals mm² area as explained in the article).

- Approximate breaking load assumes a material tensile strength ≈ 50 MPa (50 N/mm²) for the P-40 formulation; actual batch values will vary.

- Working load uses a conservative safety factor (SF) of 8 for continuous service; specific applications with dynamic shock or high-cycle fatigue may require larger SFs.

- Recommended pulley diameters are guidelines to limit bending stress and extend service life: minimum ~8× belt diameter; preferred ~10× belt diameter.

Materials and Build Quality

The Polyurethane Round Belt is manufactured from a P-40 grade thermoset polyurethane compound. Key material characteristics and manufacturing insights are detailed below.

Material Composition and Properties

- Polyurethane base: polyester- or polyether-based PU chemistry, optimized for hardness and tensile strength. P-40 denotes a formulation tuned for mechanical properties consistent with Shore 92A.

- Shore Hardness: approximately 92A — high surface strength with limited surface deformation under load.

- Tensile strength: nominally around 50 MPa (50 N/mm²) for this grade; exact values should be confirmed from lot-specific test certificates.

- Elongation at break: typically ~300% (±50%). Such elongation provides flexibility while retaining strong elastic recovery after deformation.

- Density: ~1.15–1.25 g/cm³; 1.20 g/cm³ is used for the mass estimations above.

- Operating temperature: continuous service typically from -40°C up to +80°C. Short-term exposure to temperatures up to ~100°C is possible but long-term exposure at elevated temperatures accelerates oxidative aging and stiffness increase.

- Chemical resistance: good resistance to mineral oils, greases, many aliphatic hydrocarbons and some solvents. Limited resistance to strong ketones, concentrated acids, and some chlorinated solvents — compatibility checks recommended for each chemical environment.

Manufacturing and Quality Control

Belts are produced via extrusion followed by controlled vulcanization/crosslinking processes to achieve consistent mechanical properties and dimensional stability. Quality control steps include:

- Dimensional verification (diameter tolerance ±0.1 mm typical for standard sizes).

- Hardness testing (Shore A) across production batches.

- Tensile and elongation tests on sample strips pulled from the same compound lot.

- Visual inspection for surface defects, contaminant inclusion, or voids.

- Adhesion testing and traceability for bonded loops where provided.

Key Features

The product’s technical and operational advantages can be summarized in the following features:

- High tensile capacity: enables smaller diameters to handle loads normally requiring larger belts.

- Excellent abrasion resistance: designed for long life where particulate contamination and repeated flexing are present.

- Chemical & grease resistance: suitable for oily production environments and many cleaning solvents.

- Low stretch and precise indexing: predictable elongation behavior supports accurate positioning in automation equipment.

- Field-joinable: can be joined in-situ using a manual adhesive joining tool — reduces downtime and simplifies replacements.

- Wide size range and customizability: standard diameters from 2–12 mm and custom diameters on request.

- Low moisture uptake: minimal swelling or property degradation in humid environments.

- High hardness: reduces surface deformation on small pulleys and improves traction with crowned or knurled pulleys.

Use Cases and Industry Applications

The P-40 polyurethane round belt is engineered for environments where small cross-section, durability and chemical resistance are important. The following sections describe representative use cases and design considerations for each.

Packaging and Parcel Handling

Small-diameter round belts are widely used in single-line conveyors for carton, pouch and parcel handling where gentle transport and accurate spacing are required. The P-40 compound provides:

- Longer life against abrasive debris (paper dust, dirt).

- Resistance to lubricant and oil contamination from adjacent equipment.

- Minimal creep and reliable indexing for accumulating conveyors.

Automated Assembly and Robotics

In pick-and-place and assembly systems, the combination of compact geometry and precise elongation characteristics makes round belts ideal for timing and light-drive applications. The high hardness and tensile strength reduce elongation drift and improve repeatability in motion control systems.

Printing, Textile and Web Handling

Round belts are often used for edge or center drives in web transport. The P-40 compound resists abrasion from dust and fibers while maintaining consistent traction and tension over long operational cycles.

Food and Pharmaceutical Equipment (Non-Contact)

Where contact is incidental and the application does not require FDA food-grade certification, these belts provide durable, clean-running solutions resistant to aqueous wash-downs and many cleaning agents. For direct food contact or sterilizable systems, verify material FDA/USP approvals and supplier documentation.

General Industrial Drives and Small Transmissions

Round belts are also used in small motor drives, cooling fans, blowers and instrumentation. Their simple routing and joinability allow maintenance teams to perform quick replacements without full machine disassembly.

Comparison with Similar Products

To help selection, the table below compares the P-40 polyurethane round belt with alternative round belt materials — natural rubber (NR), nitrile rubber (NBR) and silicone — across technical characteristics frequently considered in design.

| Property | P-40 Polyurethane (Shore ~92A) | Natural Rubber (NR) | Nitrile Rubber (NBR) | Silicone |

|---|---|---|---|---|

| Tensile Strength | High (≈ 45–55 MPa) | Medium (≈ 20–30 MPa) | Medium-High (≈ 20–35 MPa) | Low-Medium (≈ 6–15 MPa) |

| Abrasion Resistance | Excellent | Poor to Fair | Fair | Poor |

| Oil/Grease Resistance | Good | Poor | Good | Excellent (but other limits) |

| Temperature Range (continuous) | -40°C to +80°C | -30°C to +70°C | -30°C to +100°C (varies) | -60°C to +200°C |

| Elongation at Break | High (~300%) | Very High (~500–700%) | High (~300–500%) | Very High (~300–800%) |

| Flex Fatigue Resistance | High | Medium | Medium | Low-Medium |

| Joinability (field) | Adhesive joining possible; strong bonds | Mechanical splicing or adhesives | Adhesives/ vulcanization | Limited; adhesives less effective |

| Typical Applications | Material handling, conveyors, drives | General drives, low-cost belts | Oily environments, fuel handling | High-temp, medical, food-grade (if approved) |

Interpretation: P-40 polyurethane round belts provide an excellent balance of tensile and abrasion properties with good chemical resistance, making them favorable where durability and oil resistance are important. Silicone offers superior high-temperature performance but lacks abrasion resistance and tensile strength. Natural rubber offers high elongation and low cost but is less suitable for oily or abrasive environments.

Benefits and Limitations

Benefits

- Durability: High resistance to abrasion and fatigue extends useful life compared with many elastomeric alternatives.

- Compactness: High tensile strength per unit cross-section allows smaller diameter belts to handle comparable loads.

- Chemical resilience: Compatible with oils, greases and many solvents common in industrial operations.

- Field-joinable: Fast, low-downtime joining with the proper manual adhesive tool and procedure.

- Predictable mechanical performance: Low creep and stable modulus over time when used within recommended conditions.

Limitations

- Temperature sensitivity: Continuous use above ~80°C accelerates aging and reduces mechanical performance. Not suitable for high-temperature ovens unless specifically formulated.

- Chemical exceptions: Not universally resistant — strong ketones (e.g., MEK), certain chlorinated solvents, and concentrated acids/bases may attack the polymer. Always validate compatibility prior to specifying.

- Cost: Higher-performance PU formulations typically cost more than natural rubber alternatives; cost must be balanced against longer service intervals and reduced downtime.

- Joining requires correct adhesive process: while joinability is an advantage, poor surface preparation or incorrect adhesive choices can produce weak joints and early failure.

- Misuse at small pulley diameters: bending fatigue will be elevated if pulleys below the recommended diameter are used; this reduces life significantly.

Design and Installation Guidance

Engineering a reliable system around polyurethane round belts requires attention to tensioning, pulley design, alignment and joining. The following practical guidance helps achieve predictable performance.

Initial Tension: 3–5% Recommendation

For optimum traction, minimal slippage and minimal elongation-induced drift, an initial installed tension of approximately 3–5% of the belt span (percent elongation of the belt loop length) is recommended. Example: for a round belt loop of 1000 mm installed length (span around pulleys), initial static elongation should be set to 30–50 mm (3–5% of 1000 mm).

How to set tension:

- Measure the unloaded loop circumference (or approximate installed length).

- Increase the belt length by 3–5% (e.g., slip the belt over the pulleys while the system is stationary and adjust take-up until the targeted elongation is achieved).

- Confirm tension with a belt tension meter or by measuring deflection under a known mid-span load and adjusting to recommended tension-deflection curves for the belt diameter (consult supplier for belt-specific tension-chart if available).

Pulleys and Sheaves

- Use crowned, knurled or rubberized pulleys to improve tracking and reduce localized slip; however, excessive knurling can accelerate belt wear.

- Maintain pulley diameters at or above the recommended minimum (≈8× belt diameter). For extended life and lower bending stress use ≈10× belt diameter.

- Ensure alignment (parallelism and concentricity) to minimize side loads and uneven wear.

Maximum Operating Speed

Maximum allowable belt surface speed depends on application, temperature and lubrication. As a conservative working guideline for small round polyurethane belts, limit linear surface speeds to the range 3–5 m/s for continuous duty. Higher peak speeds can be tolerated for intermittent duty but increase heat generation and accelerate aging.

Joining Procedure (Field Adhesive Joining)

One of the advantages of this product is on-site joining using a manual adhesive tool. The general joining process follows:

- Preparation: Clean and degrease the belt ends thoroughly using isopropyl alcohol or an equivalent solvent. Remove any processing oils and contaminants.

- Abrasion: Lightly abrade the mating surfaces with fine abrasive (e.g., 240–320 grit) to increase surface area for adhesion. Wipe clean.

- Primer (if required): Apply primer recommended by the adhesive manufacturer for polyurethane bonding; allow appropriate flash-off per adhesive data sheet.

- Adhesive application: Apply the specified polyurethane- or cyanoacrylate-based adhesive in a thin, even layer to both mating ends.

- Tooling and clamping: Bring ends into close contact inside the manual adhesive joining tool that holds alignment and required pressure while cure proceeds.

- Cure: Allow the adhesive to cure fully per the manufacturer’s specified time and temperature before applying tension or placing into service.

- Post-cure inspection: Verify joint integrity via tension testing — visually inspect for voids, inclusions, or misalignment. Trim any excess adhesive bead carefully.

Note: Use only adhesives approved for the specific polyurethane chemistry. Adhesives vary widely in suitability; consult the adhesive supplier for compatibility and recommended cure profiles.

Maintenance and Care Guide

Routine maintenance maximizes belt life and reduces unexpected downtime. The following maintenance schedule and checks apply to most installations using the P-40 polyurethane round belt.

Daily/Shift Visual Checks

- Inspect for visible wear, cuts or gouges along the belt length.

- Verify belt alignment and tracking; confirm no edge rubbing on frames or guides.

- Check for contamination accumulation (excessive dust, chips, oil pooling).

Weekly Checks

- Measure belt tension and retension to 3–5% installed elongation if necessary.

- Inspect pulleys for wear, sharp burrs, or knurling wear that could abrade the belt.

- Verify joining seams for secure adhesion and absence of peel or delamination.

Monthly to Quarterly Maintenance

- Perform a detailed inspection of pulley diameters and surface condition; replace or recondition when wear affects tracking or increases stress concentrations.

- Check environmental exposure: high-temperature areas or chemical spray should be reviewed for compatibility.

- Lubrication of bearings, idlers and related mechanical components — avoid contaminating the belt unless the lubricant is compatible.

Cleaning

- For light soiling, wipe with a clean cloth and isopropyl alcohol or mild detergent solutions compatible with polyurethane. Rinse with water and dry thoroughly.

- Avoid strong solvents (e.g., concentrated acetone, MEK) that could soften or swell the polyurethane.

- Frequent exposure to cleaning agents should be validated for compatibility; if in doubt, perform a small-area soak test and inspect for hardness changes, swelling, or surface crazing.

Signs of Impending Failure

Watch for these specific failure indicators:

- Progressive reduction in belt diameter or severe abrasion along one side — indicates misalignment or abrasive contamination.

- Cracks or surface crazing — often due to chemical attack, ozone degradation or prolonged over-temperature exposure.

- Bonded seam separation — indicates poor joint preparation, improper adhesive choice, or excessive dynamic loading beyond design limits.

- Permanent elongation (set) beyond expected range — may indicate creep due to excessive static tension or continuous overload.

Troubleshooting and Failure Modes

Understanding the root causes of problems reduces repeat failure and maintenance time. Common failure modes and remedies include:

Excessive Wear

- Causes: abrasive contamination, sharp pulley edges, incorrect pulley hardness, or insufficient pulley diameter.

- Remedies: increase pulley diameter, use rubber-coated pulleys to reduce wear, improve sealing to prevent ingress of particulates, rework pulley surfaces.

Joint Failure

- Causes: improper surface prep, wrong adhesive, inadequate clamping or cure, or high cyclic bending at seam.

- Remedies: redo joining with thorough cleaning and proper primer/adhesive, consider mechanical splice or replace with pre-mounted continuous loop where available.

Slip at Pulley

- Causes: insufficient initial tension, overloaded belt, contaminated surface (oil), or inadequate pulley diameter/finish.

- Remedies: increase initial tension to 3–5%, clean belt and pulley contact surfaces, select a pulley with better friction surface, or choose a larger belt.

Chemical Degradation

- Causes: exposure to incompatible solvents, acids or bases; elevated temperature accelerates attack.

- Remedies: isolate belt from chemical exposure, select a chemically-resistant belt chemistry, or implement protective covers/shields.

Quality, Procurement and Ordering Information

When specifying or ordering Polyurethane Round Belts (P-40, Shore ~92A), include the following information to ensure correct supply and fit:

- Nominal diameter required (e.g., 4 mm), and whether individual length or continuous loop is required.

- Installed loop length or pulley dimensions to allow factory pre-join or appropriate supplier recommendations.

- Operating environment details: continuous temperature range, exposure to oils/chemicals, presence of abrasive contaminants.

- Required certification(s), for example RoHS, REACH, or food-contact approvals if applicable.

- Preferred joining method (factory welded loop vs. on-site adhesive join), and any required spares for maintenance stock.

Regulatory and Safety Considerations

Polyurethane formulations vary. For applications with regulatory constraints (food processing, pharmaceutical contact, medical devices), ensure the belt material is explicitly certified for the intended use (e.g., FDA 21 CFR compliance, EU food contact regulations). Otherwise take these general precautions:

- Use personal protective equipment when handling adhesives or solvents during joining.

- Ensure adequate ventilation when adhesives or primers release volatile organic compounds during cure.

- Follow material safety data sheets (MSDS/SDS) provided by the manufacturer for safe handling and disposal.

Conclusion

The Polyurethane Round Belt (P-40, Shore ~92A) offers a robust, compact, and versatile solution for demanding light- to medium-duty conveying and drive applications. Its combination of high tensile strength, excellent abrasion resistance, and chemical resilience makes it an excellent choice where durability and reduced downtime are priorities. Standard diameters spanning 2–12 mm provide broad compatibility with common small-drive and conveyor systems, while custom sizes and field-joinability reduce installation complexity and inventory requirements.

For designers and maintenance engineers, the key takeaways are:

- Use an initial installed tension of 3–5% to optimize traction and minimize creep.

- Observe recommended pulley diameters (minimum ~8× the belt diameter, preferred ~10×) to limit bending fatigue.

- Select adhesives and join methods appropriate to the polyurethane chemistry to achieve durable field joins.

- Perform routine inspections and alignments to maximize life and system uptime.

For critical applications, request material test data and supplier recommendations for tension charts, pulley profiles, and adhesive systems. In many installations, the P-40 polyurethane round belt delivers measurable operational benefits — longer life, reduced maintenance, and improved reliability — justifying its selection in both new designs and retrofit projects.

If you need detailed engineering support, customized belt dimensions, joint samples or batch-specific test certificates (tensile, hardness, elongation), contact your supplier engineering representative to obtain the exact data and test reports required for final design validation.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.