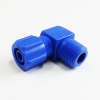

PY Union Y — One-Touch Push-to-Connect Pneumatic Union Fitting

Product Overview: The PY Union Y is a one-touch pneumatic union fitting engineered to provide rapid, tool-free connection and disconnection of tubing in compressed-air systems. Optimized for compact installations, available in both metric and inch tube sizes, and offered with PT (R) and NPT thread options, the PY Union Y is designed for repeatable, leak-resistant performance in distribution lines, automation equipment and applications where space and speed are at a premium.

Introduction

Pneumatic systems in modern manufacturing and automation demand components that are fast to install, reliable in operation, and compact in design. The PY Union Y addresses these needs with a push-to-connect (PC) union fitting that enables secure tube joining and quick disassembly without tools. Its one-touch mechanism reduces assembly time, improves serviceability and minimizes the potential for assembly errors in the field. This article provides a detailed technical review of the PY Union Y including product functions, technical specifications, materials and build quality, installation guidance, maintenance instructions and comparison to alternative fittings.

Technical Overview

The PY Union Y is a push-in union fitting that joins two lengths of tubing or transitions tubing to a threaded port. The core functionality is based on a collet-and-seal system: the user inserts a prepared tube into the fitting until it reaches a positive stop; internal stainless-steel teeth in the collet grip the tubing while an elastomeric O-ring provides the static seal. To remove the tubing, the user depresses the release sleeve which disengages the collet, allowing the tube to be pulled free. Connection and disconnection each take approximately 1–2 seconds.

Key operating parameters:

- Recommended medium: Compressed air only (dry or lubricated as specified).

- Operating pressure: 0–150 PSI (0–990 kPa).

- Vacuum capability: Down to -29.5 in Hg (-750 mm Hg / ~10 Torr).

- Operating temperature range: 0–60°C (32–140°F).

- Available tube sizes: Metric: 4, 6, 8, 10, 12, 16 mm. Inch: 5/32″, 3/16″, 1/4″, 5/16″, 3/8″, 1/2″.

- Thread options: PT (R) and NPT as appropriate to model.

Design Highlights

- One-touch push-to-connect action: Instant push-in tube insertion with rapid-release sleeve for tool-free removal.

- PC-type union with internal and external hex faces: Tightening and access are improved in compact spaces where wrench clearance is limited.

- Thread joints supplied with seal coating: A factory-applied thread seal coating reduces assembly time and ensures consistent sealing performance for threaded connections.

- Compact profile: Optimized for installations where space and weight are constrained (panels, manifolds, valve islands).

Specifications and Dimensions

Below is a consolidated specification and dimensional table covering the principal PY Union Y variants. The dimensions listed are representative nominal values used for system design and installation planning. Always confirm the dimensions for the specific part number when designing a mating component or bracket.

| Model | Tube OD | Thread Type | Thread Size | Thread OD (mm) | Overall Length L (mm) | Hex Flats (mm) | Insertion Depth (mm) | Weight (g) | Max Pressure (PSI) |

|---|---|---|---|---|---|---|---|---|---|

| PY04 | 4 mm | PT / NPT | 1/8″ | 9.7 | 28 | 10 | 9 | 6 | 150 |

| PY06 | 6 mm | PT / NPT | 1/8″ or 1/4″ | 9.7 / 13.7 | 30 | 11 | 11 | 8 | 150 |

| PY08 | 8 mm | PT / NPT | 1/4″ | 13.7 | 34 | 13 | 12 | 12 | 150 |

| PY10 | 10 mm | PT / NPT | 3/8″ | 17.1 | 38 | 15 | 14 | 18 | 150 |

| PY12 | 12 mm | PT / NPT | 1/2″ | 21.4 | 42 | 17 | 16 | 28 | 150 |

| PY16 | 16 mm | PT / NPT | 1/2″ | 21.4 | 48 | 19 | 20 | 40 | 150 |

| PY-5/32 | 5/32″ | NPT | 1/8″ | 9.7 | 28 | 10 | 9 | 6 | 150 |

| PY-3/16 | 3/16″ | NPT | 1/8″ | 9.7 | 30 | 11 | 11 | 8 | 150 |

| PY-1/4 | 1/4″ | NPT | 1/4″ | 13.7 | 34 | 13 | 12 | 12 | 150 |

| PY-3/8 | 3/8″ | NPT | 3/8″ | 17.1 | 38 | 15 | 14 | 18 | 150 |

| PY-1/2 | 1/2″ | NPT | 1/2″ | 21.4 | 48 | 19 | 20 | 40 | 150 |

Notes: Dimensions are nominal. Consult the product drawing for tolerance-critical applications. Insertion depths refer to the distance from the tube end to the internal stop; ensure the tube end is visible at the inspection window or mark to confirm correct engagement.

Materials and Build Quality

The PY Union Y is engineered from a combination of metallic and polymeric materials selected to balance durability, chemical compatibility with compressed air, weight and cost. The following breakdown outlines the typical materials used in the construction and the technical advantages each offers:

- Main body: Nickel-plated brass (standard) — provides high strength, corrosion resistance and thermal stability. The metal body reduces the risk of thread deformation during tightening and improves durability in repetitive service environments.

- Sleeve / release ring: High-strength engineering thermoplastic such as PBT (polybutylene terephthalate) or acetal (POM) — provides a smooth release action and resistance to wear, while maintaining dimensional stability across the operating temperature range.

- Collet / gripping teeth: Stainless steel — hardened stainless teeth ensure consistent grip on tubing, resist corrosion and maintain clamping force over many insertion/removal cycles.

- Sealing elements (O-rings): Nitrile rubber (NBR) standard — suitable for compressed air and common lubricants within the operating temperature limits. Optional FKM (Viton) is available for higher temperature or different chemical environments upon request.

- Thread sealing: Factory-applied liquid sealant/coating on threaded surfaces — designed to eliminate the need for additional PTFE tape in standard assembly and to provide consistent sealing performance.

Build quality is optimized for compact installations. The PC-type design integrates both internal and external hex faces that allow a wrench to access the fitting when space is constrained. Sealing surfaces are machined to tight tolerances to ensure surface-to-surface contact with the elastomeric seal; the result is a fitting that meets practical field longevity expectations under typical pneumatic conditions.

Key Features

The PY Union Y incorporates a set of features tailored for modern pneumatic system requirements. The following points highlight the principal advantages:

- Fast, tool-free tube connection/disconnection: Push-in insertion and sleeve-release disconnection decrease assembly and maintenance times.

- Compact PC-type geometry: Saves panel and manifold space and facilitates neat tubing routings in high-density assemblies.

- Metric and inch compatibility: Available for a wide range of tube diameters to match regional and application-specific tubing standards.

- Threaded connection options: PT (R) and NPT threading accommodate various port standards and system designs.

- Pre-applied thread seal coating: Simplifies on-site assembly and reduces variability from field-applied tape or sealant.

- Vacuum-capable: Rated to roughly 10 Torr, suitable for many low-pressure and vacuum applications in automation.

- Repeatable sealing: Engineered O-ring and collet combination provides consistent, leak-minimized joints over multiple service cycles.

- Serviceability: The external hex face provides a positive wrenching surface for installation in tight locations where internal access is limited.

Model Coding and Part Numbering

Understanding the model coding makes ordering and documentation straightforward. The PY-series uses a simple model code format that shows model type, tube diameter and thread size. Examples:

- PC-06-1/8 — PC-type, 6 mm tube diameter, 1/8″ thread.

- PY08 — PY-series model for 8 mm tube size (thread option determined by suffix or separate part number).

- PY-1/4 — Inch-variant for 1/4″ tube size.

When specifying parts for procurement, include the tube OD, desired thread standard (PT or NPT), and any options such as alternate O-ring material or special plating.

Use Cases and Applications

The PY Union Y is suitable for a broad range of pneumatic applications where speed of installation, compact footprint and repeatable sealing are required. Typical use cases include:

- Pneumatic distribution lines: Efficiently create lateral or inline connections in air supply manifolds and spur lines within machine cabinets.

- Automation equipment: Used on pick-and-place machines, conveyors, robotic end-of-arm tooling and actuators where rapid servicing and frequent reconfiguration occur.

- Valve islands and solenoid manifolds: Compact unions allow near-valve connections with minimal leakage risk and quick field changes.

- Packaging and assembly lines: Fast changeovers benefit from tool-free disconnection for modular tooling and quick maintenance.

- Laboratory and instrumentation systems: Low-pressure vacuum capability supports certain lab pneumatic and vacuum test setups (verify chemical compatibility before use).

- Field service and maintenance kits: Because these unions require no tools, they are practical components for mobile service carts and field spares.

Comparison with Alternative Fittings

To aid component selection, the table below compares the PY Union Y with other common union fittings: a standard threaded union (metal union), a push-in straight union, and a barbed union. The comparison emphasizes attributes important to system designers: installation speed, space efficiency, reusability, sealing reliability and suitability for vacuum.

| Attribute | PY Union Y (push-to-connect) | Threaded Metal Union | Push-In Straight Union | Barbed Union |

|---|---|---|---|---|

| Installation Speed | Very fast — one-touch insertion, rapid-release | Slow — requires tape/sealant and torque | Fast — push-in; often larger profile | Moderate — requires hose clamp |

| Space Efficiency | High — compact PC-type geometry | Medium — bulkier threads and unions | Medium — can be longer straight bodies | Low — hose clamps add bulk |

| Tool-Free Disconnection | Yes | No | Yes | No (requires tool to remove clamp) |

| Sealing Reliability | High — engineered O-ring and seal coating | High if properly installed | High — similar technology | Medium — dependent on clamp quality |

| Vacuum Suitability | Yes (limited to ~10 Torr) | Yes (depends on sealant) | Yes (varies by model) | Limited — generally poor for high vacuum |

| Service Life (cycles) | High — designed for frequent cycles; periodic O-ring replacement recommended | High — robust but slower to change | Variable — similar to PY Union | Low — hose material and clamps degrade faster |

| Recommended Media | Compressed air only | Compressed air and non-aggressive gases | Compressed air and inert gases | Compressed air; liquids if hose-compatible |

Benefits and Limitations

Benefits

- Time savings: Rapid one-touch connections reduce assembly and maintenance time, translating directly into lower labor costs for installations and changeovers.

- Compact and serviceable design: The PC-type geometry with internal/external hex faces is well-suited to tight installations where wrench clearance is constrained.

- Repeatable sealing: Factory-applied thread seal coating and precision O-rings deliver consistent performance and reduce variability from field-applied tape.

- Wide size range: Availability in both metric and inch tubing sizes allows global and multi-standard deployment without adapter components.

- Vacuum capability: The PY Union Y can be used in low-vacuum applications, offering flexibility beyond simple positive-pressure systems.

Limitations

- Media restriction: Designed and rated for compressed air only. Use with other gases or liquids is not recommended unless verified by the manufacturer.

- Temperature range: Limited to 0–60°C (32–140°F) in standard configuration. For higher temperatures, alternate O-ring materials and body options would be required.

- Pressure limit: Rated to 150 PSI (990 kPa). For high-pressure pneumatic or hydraulic systems, alternative fittings must be used.

- Wear from cyclic operations: Repetitive insertions/removals will eventually wear the O-ring and collet teeth; service intervals should be planned accordingly.

- Tubing material sensitivity: The collet grip is optimized for commonly used pneumatic tubing such as PU and nylon. Soft or brittle tubing may deform under clamping force or be difficult to seal reliably.

Installation and Best Practices

Proper installation ensures the PY Union Y achieves nominal performance. Follow these recommendations during assembly and commissioning:

- Inspect the tube end: Cut tubing squarely using a sharp utility cutter or tubing cutter. Deformed, chewed or angled ends can prevent the tube from reaching the internal stop and may compromise sealing.

- Deburr and clean: Remove any external burr or swarf from the cut end. Wipe the tube with a clean cloth to remove dust, oil or cutting residue.

- Verify tubing compatibility: Use tubing of the specified OD and recommended materials (polyurethane, nylon, soft nylon). Confirm wall thickness if required by system designers.

- Insertion technique: Push the tube into the fitting firmly until it contacts the positive internal stop. If in doubt, mark the insertion depth on the tube to verify engagement.

- Threaded port installation: The fitting is supplied with a factory-applied thread seal coating; additional sealant is not normally required. If installing into PT (R) or NPT ports, tighten using the appropriate wrench on the hex flats. Avoid over-torquing.

- Tightening torque guidelines (typical): Use conservative torque values appropriate for the thread size and material. Typical recommended ranges (for metal-bodied fittings into metal ports): 1/8″ — 4–6 N·m; 1/4″ — 6–10 N·m; 3/8″ — 8–12 N·m; 1/2″ — 10–18 N·m. These values are general guidance; follow port manufacturer recommendations and avoid over-stressing plastic ports.

- Leak testing: After assembly, perform a pressure test using soapy water or a calibrated leak detector. Inspect for bubbles at the tubing-to-fitting interface and at threaded connections.

- Service access planning: Because the PY Union Y supports tool-free removal, ensure adequate clearance to depress the release sleeve when planning the assembly layout.

Installation Tips for Tight Spaces

- Use the external hex face for final tightening when the internal hex cannot be accessed by a socket or hex wrench.

- For installations on panels or manifolds, assemble the fitting into the port first, then route tubing to minimize stress on the fitting connection.

- Use short coupling lengths and avoid sharp bends at the fitting entry; maintain minimum bend radii specified for tubing type to prevent kinking and undue collet stress.

Maintenance and Care Guide

Appropriate maintenance prolongs the service life of the PY Union Y and reduces downtime. The following maintenance procedures are recommended for industrial use:

Routine Inspection

- Inspect fittings visually during scheduled maintenance intervals (e.g., monthly or quarterly depending on system duty cycle) for signs of wear, damage or leakage.

- Check for abrasion or cuts on tubing close to the collet area. Replace tubing that shows signs of surface damage.

- Confirm the release sleeve operates smoothly. If the sleeve sticks, clean debris from the collet area or replace the fitting if corrosion or damage is present.

Replacement of Wear Items

- Replace O-rings if leakage is detected at the tube-to-fitting seal. Standard O-rings are NBR; replacements should be of equal hardness (durometer) and certified for the application environment.

- If collet teeth become rounded or fail to grip tubing securely, replace the fitting. The collet is a critical component that is not normally field-serviceable on all models.

- Record the number of insertion/removal cycles in critical applications; schedule proactive replacement after a defined lifecycle for predictable uptime.

Cleaning

- When cleaning the system, avoid solvents that may degrade the elastomeric seals (check compatibility). Use mild detergent and water, followed by drying.

- Do not use petroleum-based cleaners or silicone oils on components containing NBR O-rings; these agents can swell or soften the elastomer and reduce sealing performance.

Storage and Handling

- Store fittings in a dry, ambient-temperature environment away from direct sunlight and ozone sources to protect elastomers.

- Protect threads and sealing surfaces with caps or packaging to prevent contamination and mechanical damage prior to installation.

Testing and Quality Assurance

Manufacturers typically perform dimensional checks, pressure and leak tests, and cycle testing to validate product performance. Recommended factory or shop checks for assemblies using PY Union Y fittings include:

- Pressure test: Pressurize to maximum system operating pressure (or 1.5× system pressure for commissioning where appropriate) and verify no leakage.

- Cycling test: For high-cycle applications, validate a subset of fittings undergo a defined number of connect/disconnect cycles to confirm operational life.

- Vacuum test: For vacuum applications, validate the assembly under the expected vacuum level to check for any outgassing or leak paths.

- Helium or mass spectrometer leak detection: For critical systems, use helium leak detection to quantify small leak rates if necessary.

Design Considerations and System Integration

When designing pneumatic systems with the PY Union Y, consider the following technical points to ensure high reliability and ease of maintenance:

- Tube routing: Avoid creating torsional loads on the fitting from misrouted or tensioned tubing. Provide strain relief where tubing exits cabinets or panels.

- Pressure spikes: Protect fittings from pressure spikes exceeding the rated 150 PSI (990 kPa). Where such spikes are possible, incorporate pressure surge protection or relief valves into the system design.

- Material compatibility: For systems involving oil-laden air or specific lubricants, verify elastomer compatibility. Standard NBR is generally tolerant of lubricated air, but consult the manufacturer if unusual lubricants are used.

- Thermal considerations: Keep fittings away from localized heat sources that could elevate temperatures above 60°C. For higher-temperature environments, request parts with elevated-temperature elastomers.

- Panel and manifold holes: Provide adequate clearance for the outer hex and body length during installation. When integrating into manifolds, ensure port thread engagement meets minimum thread engagement depth.

Application Examples — Real-World Scenarios

Below are practical examples illustrating how the PY Union Y can be used in different environments:

1. Packaging Machine Changeover

In a packaging line that requires frequent tooling changeovers, PY Union Y fittings enable operators to disconnect pneumatic lines for individual tooling modules in seconds—without tools—reducing downtime during format change. The compact fitting allows dense valve manifold packing while maintaining easy field access for quick release.

2. Robotic Gripper Maintenance

End-of-arm tooling often requires removal for maintenance or replacement. The PY Union Y enables quick disconnection of actuator lines; the push-to-connect action ensures repeatable sealing when the gripper is reinstalled. The vacuum capability also supports toolings that rely on low vacuum for workholding.

3. Laboratory Pneumatic Bench

In a lab bench with multiple experimental setups, the ability to rapidly reconfigure tubing and sensors is essential. The PY Union Y provides a reliable, low-leak means to join tubing across experiments without needing specialized tools or risking damage to delicate components.

Troubleshooting Guide

Some common issues and their resolutions:

- Leak at tube entry: Check that tubing is fully inserted to the positive stop and cut squarely. Remove and re-insert after cleaning. If leakage persists, inspect O-ring for damage and replace the fitting if necessary.

- Collet will not grip tubing: Inspect collet teeth for contamination or damage. Clean or replace if necessary. Verify tube OD and wall thickness meet the specified tolerances.

- Threaded joint leaks: Confirm the joint has been tightened to appropriate torque and that the factory-applied seal coating is intact. For repeated disassembly, consider applying fresh thread sealant compatible with pneumatic use.

- Release sleeve is stiff or stuck: Debris or corrosion may be present. Depress sleeve and apply appropriate cleaning (mild detergent for external surfaces). If the sleeve still does not move freely, replace the fitting.

Regulatory and Safety Considerations

When integrating the PY Union Y into systems, observe relevant industry and regulatory guidelines:

- Design systems to include pressure relief and emergency shutdown provisions as required by local safety codes.

- Ensure materials and seals are selected to match any required compliance for cleanliness or gas compatibility (e.g., food industry, medical applications may require specific materials and cleaning regimens).

- Consider operator safety when placing quick-disconnect fittings in accessible areas; accidental disconnection under pressure can cause sudden motion or ejection of tubing.

Ordering and Part Selection Checklist

To streamline procurement and ensure the correct PY Union Y variant, compile the following information for each part number:

- Tube outer diameter (e.g., 8 mm or 1/4″).

- Thread type and size (PT/R or NPT, e.g., 1/8″, 1/4″).

- Desired O-ring material (NBR standard; FKM/Viton or EPDM if needed for special environments).

- Body material or plating preferences (standard nickel-plated brass; specify stainless-steel bodies where corrosion resistance is paramount if available).

- Quantity and any kitting or assembly requirements (e.g., mounted on manifold or pre-assembled tubing lengths).

Conclusion

The PY Union Y is a high-value component for compressed-air systems that demand rapid assembly, repeatable sealing and a compact footprint. Its push-to-connect mechanism, combined with threaded port compatibility and vacuum-capable performance, makes it versatile for a broad set of industrial and laboratory applications. Careful attention to tubing preparation, proper installation torque and periodic maintenance will help maximize the fitting’s service life and maintain low leak rates in critical pneumatic systems.

For designers and maintenance engineers, the PY Union Y reduces assembly time, simplifies service procedures and enables compact pneumatic layouts. When specifying fittings, ensure that operating conditions—media, temperature, and pressure—fall within the product’s ratings and consult manufacturer datasheets for application-specific guidance and certified part drawings.

Keywords: PY Union Y, push-to-connect, pneumatic union fitting, compressed-air fitting, push-in fitting, quick-disconnect, vacuum-capable union, PT/R, NPT.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.